However, other feed processing technologies may have limited value in swine diets. Proper feed mixing and diet sequencing is also important to maintain pig performance and minimize concerns about potential antibiotic residues. Objectives . Discuss feed processing and management considerations for the swine operation: Effects of particle size

Everything you need to know about feed pelleting in a convenient, downloadable guide, from sources you trust. The FREE Feed Pelleting Reference Guide is from WATT Global Media and K-State University, as individual, topical PDF files within each of the six sections of the guide. Borregaard LignoTech.

Chicken Feed Pellet Production Line Animal Feed Dryer Machine For Poultry Feed Formulation Machine. $2,230.00-$35,830.00/ set. 1 set (Min Order) Luoyang Luodate Machinery Equipment Co., Ltd.> CN 9 YRS. 97.5% Response Rate.

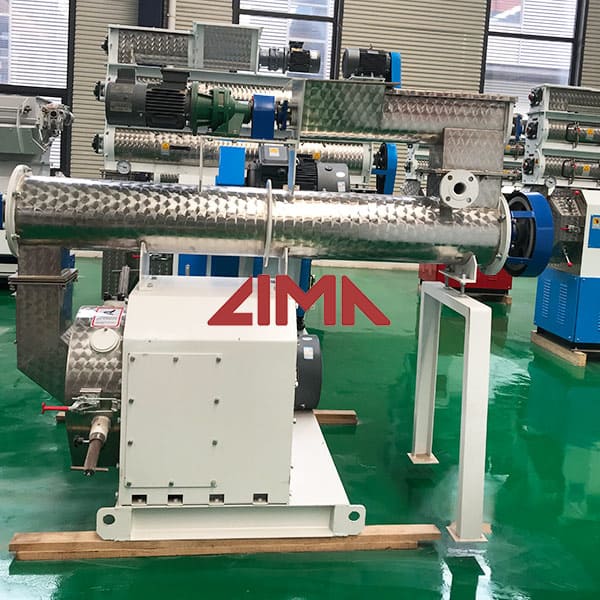

The animal feed manufacturing plant is a ring-type animal cattle feed production line, which has the characteristics of high-precision gears. The granulator is specially designed for stress-free and smooth transmission of the main shaft, long service life of the shaft, and low noise. it can be equipped with a non-stop refueling system.

2020-1-3·Photos: 1-2t/h animal feed production line. Get Price Now!: inquiry@sunwitindustry.com. Step 01: Raw Materials Reception and Cleaning Process. The first stage involves receiving and cleaning raw materials for manufacturing the feed, such as grains, beans, grass or fishmeal. Step 02: Feed Crushing Process.

2022-12-13·The formula to make pig feed pellets include a mixture of cereals, proteins and fats and additives. The most common cereals are corn, wheat bran, rice bran or sorghum. Sources of proteins and fat include bone meal, fish meal and soybean meal. Additives usually contribute to better storage or nutrition and can include spices, …

2023-2-14·Project Name: Complete Set of Livestock Feed Production Line; Production Output: 2 ton per hour; Application: Can be widely applied to make feed for ruminant animals (sheep, goat, cattle, cow, horse, camel...).; Main Equipment: Mixing machine, pellet mill, pellet cooler, bagging machine, belt conveyors and etc. Similar …

2019-11-19·Pressing is the core process of pig feed pellets production. During this process, water, temperature and steam pressure have a great influence on the mass of the final pellets. If the moisture content of the raw material is higher than 8-10%, the hardness of the particles will increase. The optimum moisture content is 16-17%.

Feed Processing Machines Feeds Pellet Machine Cattle Feed , Find Complete Details about Feed Processing Machines Feeds Pellet Machine Cattle Feed,Feed Processing Machines,Feeds Pellet Machine,Cattle Feed from Supplier or Manufacturer-Shandong Double Crane Machinery Manufacture Co., Ltd.

300mm. Size. 1360*570*1150mm. Weight. 450kg. Get Quote. Animal feed pellet machine specially produces animal feed for cattle, goats, and poultry, like chicken, and duck. This machine has the simple structure, stable performance, and easy operation. Besides, the raw materials of the animal feed pellet mill are grass and grains, like corns ...

However, other feed processing technologies may have limited value in swine diets. Proper feed mixing and diet sequencing is also important to maintain pig performance and minimize concerns about potential antibiotic residues. Objectives . Discuss feed processing and management considerations for the swine operation: Effects of particle size

2015-11-9·Specifically, when air speed decreases, drying improves at the expense of cooling quality. “Feed plants use two kinds of machinery to assure drying-cooling,” explains Fabrice Putier, director of Tecaliman, the French technical center for feed manufacturers. “They might be either horizontal or vertical, about two-third being vertical in ...

2011-5-27·For nursery feeds, pellet-cooker products were priced $9.00 per ton more than standard pelleted nursery feeds; For the next stage of starter feeds, pellet-cooker products were priced $4.20 per ton more; Despite these higher feed costs, the pig feed customers' profits were $3.40 per pig more for those fed the pellet-cooker products …

2020-10-21·1-2 t/h Pig Feed Pellet Production Line. 1.Raw materials crushing: Raw materials need to be crushed first before pelletizing. As to the materials grinding, you can weigh the raw materials according to the formula and then ground them in feed hammer mill, or you can ground them separately and then mix. This two methods are both OK and you …

1 ·The best option for Animal Feed Pellet Machines in Agriculture for Africa. Make Your Own Animal Feed from Turn-key Small to Industrial Scale Production Lines for Cows, Pigs, Sheep, Chicken and Fish. We offer a full range of tested and proven feed processing systems that make the manufacturing of animal feed both labour-saving and cost-effective.

2022-2-22·3-4t/h. SZLH35. 5-7t/h. SZLH42. 8-12t/h. SZLH50. 10-15t/h. The feed pellet production line also called feed pellet plant, cattle feed plant, poultry feed plant, feed mill plant for poultry, which is an ideal equipment for animal husbandry. It It integrates the functions of dust removing system, crushing, mixing, conveying, pelletizing, cooling ...

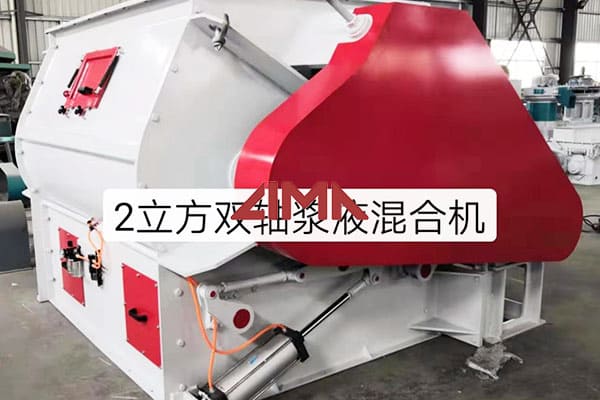

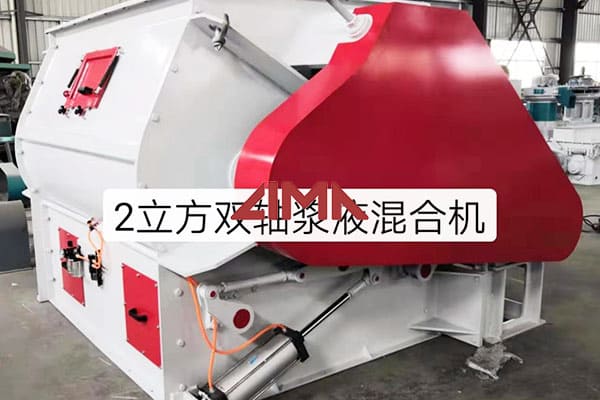

The mixing time is 5-8 minutes, and the mixing coefficient of variation CV≤5%. It is less used than a single-shaft twin-ribbon animal feed mixer machine, and is generally used for premix production. Single shaft two layer paddle, mixing time 45-60s. High evenness, mixed evenness is more than 97.7%.

Feed Processing Machines Feeds Pellet Machine Cattle Feed , Find Complete Details about Feed Processing Machines Feeds Pellet Machine Cattle Feed,Feed Processing Machines,Feeds Pellet Machine,Cattle Feed from Supplier or Manufacturer-Shandong Double Crane Machinery Manufacture Co., Ltd.