2012-6-28·Pelleting Process Evolution of fish feeds: Moist feeds; beef liver, spleen 1960 Powder mixture Semi moist feeds; trash fish and powder 1970 Dry pelleted feeds with lots of fines 1980 Extruded feeds 1990 Pelleting: to give a cylinder shape to the mixed ingredients under temperature, pressure and moisture.

2017-2-21·Expansion Control System for in-line con-trollability of extruded feed expansion/sink-ability. Flextex for easy adjustment of extru-sion SME during operation. Dryer Combi-zone dryer for improvement of fish feed and pet food, covering a variety of production capacities (up to 30 tph.) Conditioner CM series for pre-conditioning with ad-

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage. Below you ...

2019-9-9·the demand for food production, specifically as a protein source. The aquafeed mill Feed mills designed to produce aquafeed have major differences when compared to traditional animal feed mills. To understand the differences, it is necessary to have a basic understanding of an aquafeed plant layout. Figures 18-1, 18-2 and 18-3

2021-9-4·Today I will share with you a new aqua fish feed production business plan. This is a new technology 15t/h aqua fish feed plant project located in Nantong, China. The automatic running 15 tons per hour aqua feed plant project covers a total area of 75,133 m2 (approximately 112.7 acres), with a total construction area of 46,102 m2.

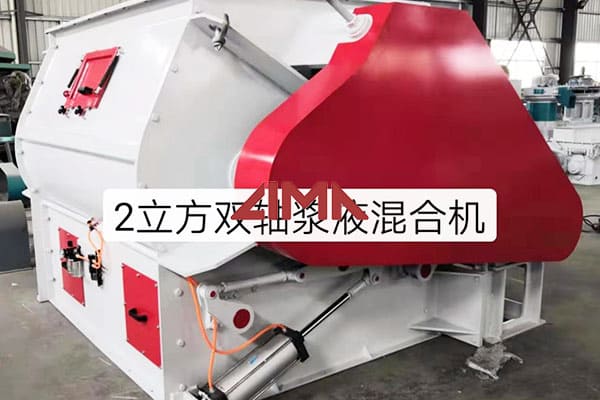

2021-2-17·3. PROCESSING. Material flow during processing includes: (a) particle size reduction, (b) premixing, (c) mixing, (d) pelleting, and. (e) sacking. Coarse ingredients pass over a permanent magnet which removes tramp metal and then through a hammer mill which reduces particle size to the desired screen analysis.

2022-11-15·One of the main differences between pelleted and extruded feed is that, whereas pellets sink, the buoyancy of the extruded feed can be controlled during the manufacturing process. However, extrusion has other advantages that we will now examine. Both manufacturing processes have common phases, but the pelletisation or extrusion …

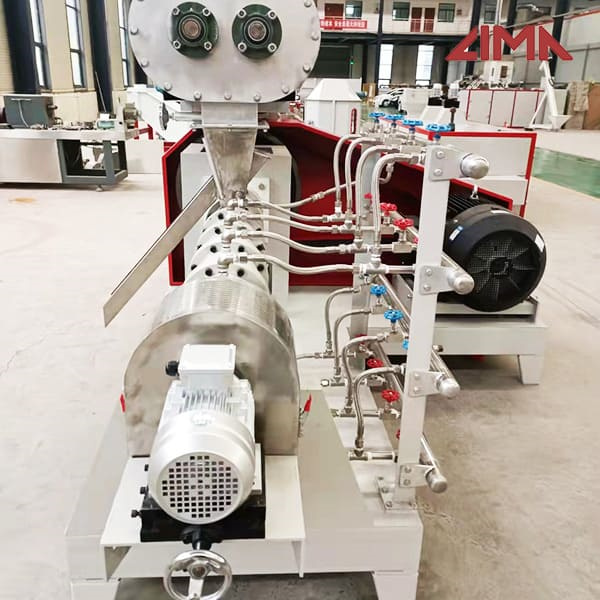

2022-12-7·Sinking Fish Feed Manufacturing Plant Display. This is a commercial scale fish feed plant with the capacity of 40 ton/h. It is designed and built for making sinking type fish feed pellets. Here are some onsite construction photos of the project for your reference. Detailed information and project cost is available if you need.

It sin 0.5θ was reduced to 125mm making a clearance of 5mm The small pulley with the highest value of 5.54 will be used as a basis for the design. Substituting the between screw and barrel. The shaft was step value of T 1 = 900N, m = 0.19 and V into the turned by 20mm at its two ends. The shaft equation.

![<h3>[PDF] DESIGN AND CONSTRUCTION OF A FISH FEED …</h3>](/wp-content/themes/lima/load/50/Chicken feed pellet machine81.jpg)

2016-8-1·Design and fabricated of a fish feed extruder with improved qualities and affordable cost, the design was carried out using engineering principles with due consideration to cost, ease of operation ...

This study was carried out with fish diet, where had been processed without steam addition (cold pelleting). The aim of the study was to explore the impact of fish feed extruder die surface holes ...

2019-9-1·Feed Pelleting Reference Guide Section 1: Introduction Chapter 5: Pellet Line Layout and Design 200 tonnes; there are two surge bins over the pellet mill and minimal die changes. The multi-species plant manufactures an array of products, including textured horse and swine feed for commercial and retail customers.

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage. Below you ...

2019-9-9·the demand for food production, specifically as a protein source. The aquafeed mill Feed mills designed to produce aquafeed have major differences when compared to traditional animal feed mills. To understand the differences, it is necessary to have a basic understanding of an aquafeed plant layout. Figures 18-1, 18-2 and 18-3

Vacuum Coater. Increase the quality and/or the energy content of your feed and introduce liquids deep into the pores of shrimp and fish feed, pellets, extrudates, poultry feed and pet food. Vacuum coating is a standard process in fish feed production. Depending on the feed type, 4 to 40 % oil are subsequently applied to the extruded fish feed.

2022-11-15·One of the main differences between pelleted and extruded feed is that, whereas pellets sink, the buoyancy of the extruded feed can be controlled during the manufacturing process. However, extrusion has other advantages that we will now examine. Both manufacturing processes have common phases, but the pelletisation or extrusion …

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

It sin 0.5θ was reduced to 125mm making a clearance of 5mm The small pulley with the highest value of 5.54 will be used as a basis for the design. Substituting the between screw and barrel. The shaft was step value of T 1 = 900N, m = 0.19 and V into the turned by 20mm at its two ends. The shaft equation.