2019-6-1·The throughput is the rate at which the feed sample fed into the machine is been recovered. This was obtained using Eq. (20). In this work, 3 kg of the homogenous feed mixture was fed into the machine and 2.2 kg of the feed was recovered at a time interval of 8 min. This gave a throughput capacity of 0.275 kg/min, which is …

Small Extruder Floating Fish Feed Machine Fish Food Pellet Processing Equipment Pet Food Dog Cat Bird Fish Puffed Extruder ... Jinan Dry Animal Pellet Food Equipment Pet Cat Dog Food Machine Floating Fish Feed Twin Screw Extruder Machinery Plant . US$ 7500-27500 ... Floating Automatic Fish Food Making Machinery; Feed Type ...

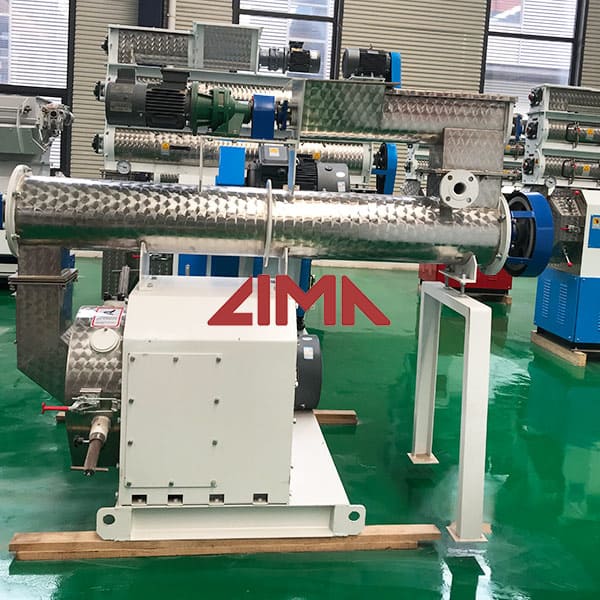

It is more suitable for extrusion processing of materials with high moisture and high oil content. Aquatic feeds, especially marine fish feeds, generally have higher fat content, so twin-screw fish feed extruders are more suitable. Capacity: 1.5-12 T/H. Price of twin-screw extruder machine: 70,000-200,000USD USD.

2014-12-17·Abstract: The performance of a developed floating fish feed extruder was evaluated. The effect of some parameters such as; screw speeds (100 rpm, 150 rpm, and 200 rpm), moisture content of ration (20 %, 25 %, 30 % and 35 %), and die diameters (3 mm, 5 mm, 9 mm) on specific mechanical energy requirements, expansion

1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is …

2016-10-2·aquaculture. Fish feed extruder comprises of hopper, a barrel which houses, the screw conveyor, the cutting knife, the die, a heater etc. It can be divided into wet and dry type mill. They both can produce floating fish feed pellets, slowing sinking pellets and sinking feed pellets. The main difference is whether need to connect a

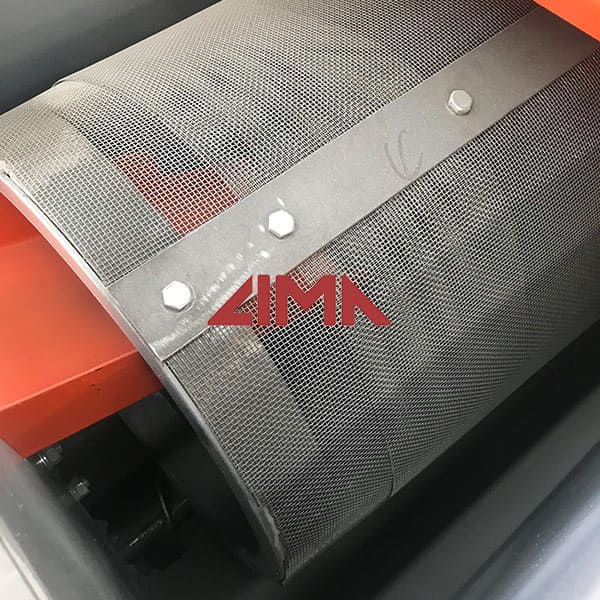

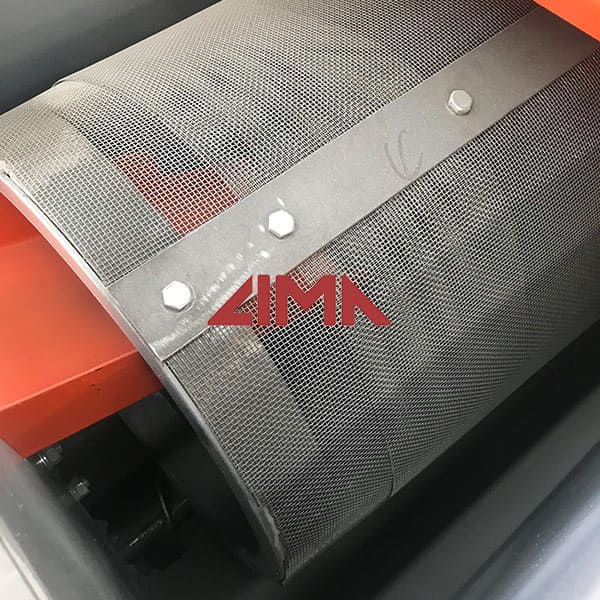

2022-12-8·This small type SZLH250 pelletizing machine is suitable for making chicken feed, cattle feed, sheep feed, pig feed, rabbit feed, etc. By changing ring die with different hole size , can manufacturer animal feed pellets at 2mm, 3.5mm, 4mm, 6mm, 8mm. This SZLH250 feed pelletizing machine is also equipped with full stainless steel of the …

It sin 0.5θ was reduced to 125mm making a clearance of 5mm The small pulley with the highest value of 5.54 will be used as a basis for the design. Substituting the between screw and barrel. The shaft was step value of T 1 = 900N, m = 0.19 and V into the turned by 20mm at its two ends. The shaft equation.

China Floating Fish Feed Extruder manufacturers - Select 2023 high quality Floating Fish Feed Extruder products in best price from certified Chinese Fish Food Machine, Feed Extruder suppliers, wholesalers and factory on Made-in-China.com ... 2021 Large Output 100-800kg/H Floating Fish Feed Production Line Making Machine Pet Food Extruder ...

The single-screw floating fish feed making machine can be used to produce various types of aquatic feeds, which can produce both high-grade and low-grade feeds. It can be used as both a floating extruded feed and a sinking extruded feed. Feed pellets range from 1 …

2014-12-17·Abstract: The performance of a developed floating fish feed extruder was evaluated. The effect of some parameters such as; screw speeds (100 rpm, 150 rpm, and 200 rpm), moisture content of ration (20 %, 25 %, 30 % and 35 %), and die diameters (3 mm, 5 mm, 9 mm) on specific mechanical energy requirements, expansion

1 ·Pellet Mill Vs. Extrusion of Fish Feeds. The process of pelletization happens inside a pellet mill. It involves creating pelleted feeds by compression of raw material, which is in powder form. This compaction happens in the presence of some moisture, temperature and pressure. Pelletized feeds are dense and heavy and thus they sink.

2014-2-1·Design and fabrication of fish feed pelleting Machine and Dryer Thesis submitted to the Department of Mechanical Engineering F,U,T Minna pp 1-79. feed milling process in fish feed technology W Hasting

As a pioneer in the development of the closely intermeshing, co-rotating twin screw extruder, we possess a unique know-how and an extraordinary wealth of experience in this field. Coperion has continuously set new standards in machine and system design for processing technology since the 1950s. More than 15,000 installed compounding systems ...

and finished pellet size can be 0.9mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, and so on till to the bigger 15mm. this fish feed making machine is multi function, except for manufacturing floating fish feed, it can also process livestock and poultry feed. the floating fish feed machine can be used to process single raw ...

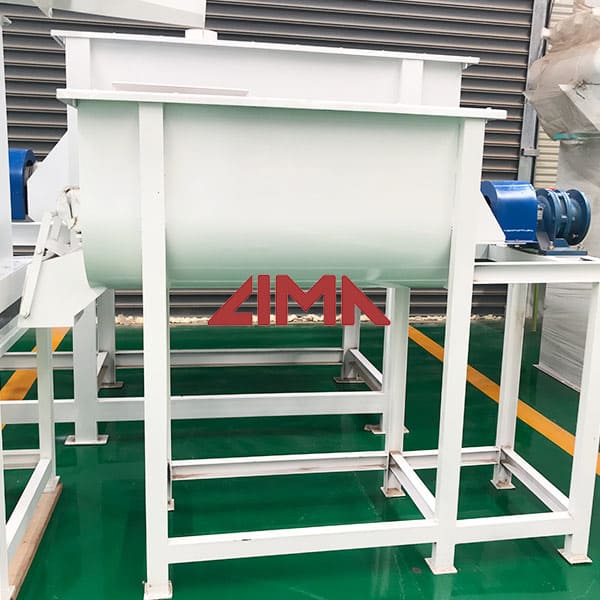

Capacities: ranging from 1 up to 42 t/h (depending on product) Reasonable cost: 7000-100000USD. Application:Suitable for all kinds of poultry, livestock and aquatic pellet feed processing Wide range of ring die sizes (diameter) : 250, 320, 350, 420, 508, 558, 678, 768, 858, etc. Delivery time: 12-30 Days .

2022-12-8·This small type SZLH250 pelletizing machine is suitable for making chicken feed, cattle feed, sheep feed, pig feed, rabbit feed, etc. By changing ring die with different hole size , can manufacturer animal feed pellets at 2mm, 3.5mm, 4mm, 6mm, 8mm. This SZLH250 feed pelletizing machine is also equipped with full stainless steel of the …

New and Used Extruder insights. There are 60 Extruder for sale in Australia from which to choose. Overall 72% of Extruder buyers enquire on only used listings, 28% on new and 4.60% on both new and used Extruder items. Buyers usually enquire on 1.40 different Extruder classifieds before organising finance.