Shrimp Feed Dryer The Wenger Four Pass Continuous 24x30 Shrimp Feed Dryer. The Mesh Screen Conveyor retains all feed while maximizing process airflow that removes moisture from the product. Heavy Duty Steam Coils ensure reliability and provide an abundance of consistent, efficient heat to the drying process. The new Direct Drive Spout …

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1... Place of Origin:Shandong, China.

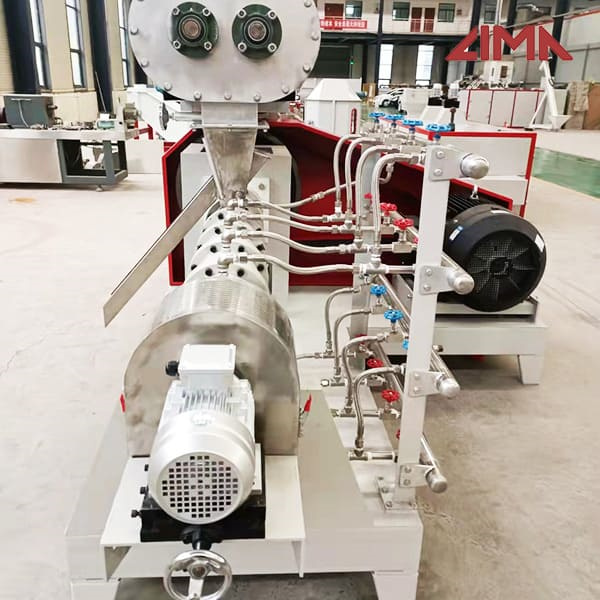

2004-4-1·Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

1 ·The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

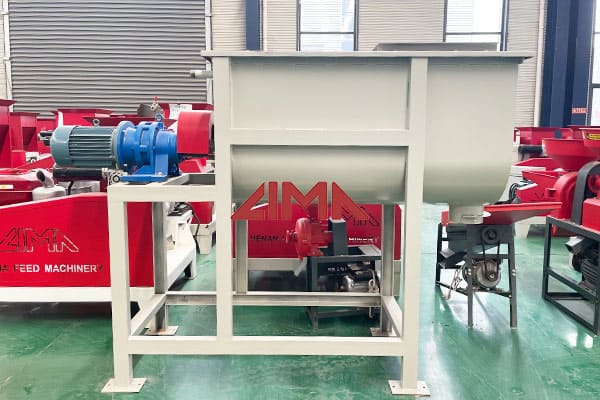

Henan ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC 080000, GMP, BSCI, BRC, SA 8000, QHSE, HACCP, BS 25999-2 ...

and finished pellet size can be 0.9mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, and so on till to the bigger 15mm. this fish feed making machine is multi function, except for manufacturing floating fish feed, it can also process livestock and poultry feed. the floating fish feed machine can be used to process single raw ...

100-150kg/h industrial diesel Floating Fish Feed Pellet Machine corn puffing snack machine with motor. +Shipping: US $405.26. Yiwu Sneeceman import&export Co. Store. US $79.9.

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

2 ·Pet Food Production Line Detail Introduction. Pet Food Production Line Detail Introduction The pet food production line is a new pet food production line successfully developed by the Loyal pet food production technology team combined with years of experience in the development of twin-screw extruders. The Loyal pet food production …

The performance of a developed floating fish feed extruder was evaluated. The effect of some parameters such as; screw speeds (100 rpm, 150 rpm, and 200 rpm), moisture content of ration (20 %, 25 %, 30 % and 35 %), and die diameters (3 mm, 5 mm, 9 mm) on specific mechanical energy requirements, expansion ratio, bulk density and pelleting …

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1... Place of Origin:Shandong, China.

2014-12-17·Performance Evaluation of Floating Fish Feed Extruder S. T. Ojo1, O. J. Olukunle2, T. O. Aduewa3 and A. G. Ukwenya4 1Department of Agricultural Engineering, ... function as the binder, other materials with lesser bulk densities compared to that of water like wheat offal, rice bran, corn, soya and so on were sources locally and powdered to ...

Aquatic Feed Extruder Price - Select 2023 high quality Aquatic Feed Extruder Price products in best price from certified Chinese Screw Extruder Machine manufacturers, China Extruder suppliers, wholesalers and factory on Made-in-China.com ... Hhphs Series Single Screw Steam Aquatic Feed Extruder China FOB Price: US$ 1-20000000 / Piece. Min ...

2019-12-30·The optimum of screw speed is 600 rpm. Meanwhile increasing of barrel temperature caused reduction of unit density, and escalation floatability of feed. Best barrel temperature to meet the ...

2023-1-29·PROCESS ENGINEERING Misr J. Ag. Eng., July 2018 - 1024 - 3-Wenger Gas-fried dryer series 4800 (two pass dryer, one pass cooler), Sabetha, KS. 4-Wenger batch mixer 5.5 HP (ribbon mixer stainless steel material) 5-Pneumatic lift system to convey product from extruder to dryer. 6- Weighing scale (Kubota), other scale used for bulk …

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.