2021-10-21·Funding for the $21.2 million facility has come exclusively from private donors, including Kent Corporation, Iowa Corn Promotion Board, Sukup Manufacturing Co., California Pellet Mill (CPM), Iowa Crop Improvement Association and NEW Cooperative. The anticipated completion date of the feed mill and grain science complex is fall 2022.

A new generation of high-feed milling cutter with high versatility. ø25 – ø160 mm – (APMX): 2.5 mm. ... -Mill. Economical 8 edged inserts with light cutting face milling cutter. ø50 – ø160 mm – (APMX): 3 mm. CeramicSpeed-Mill. High efficiency milling cutter with ceramic inserts for high temperature alloy machining. ø50.35 – ø67 ...

2023 Feed Mill of the Future Conference. Feed Strategy Staff | November 28, 2022. New Feed Mill of the Future Conference highlights technologies, investments companies can explore today to prepare for tomorrow […]

Best Price of High Efficiency Maize (Corn) Hammer Mill in Chicken and Poultry Animal Feed Mill with CE Certification. US $ 5,000-42,600 / Piece. 1 Piece (MOQ) More. Hammer Mill, Pellet Mill, Mixer, Screw Extruder, Dryer, Wood Pellet Mill, Wood Hammer Mill, Feed Machine, Feed Processing Machinery, Biomass Processing Machinery. Audited Supplier.

2021-5-27·A higher number of tons per run improves the mill’s efficiency by minimizing the number of times the operator switches to a different feed type either in the mixing or pelleting process. For operations without a pelleting line, changeovers can cost the operator approximately 5 minutes depending on the design of the system and the designated ...

New Generation Supplements Brad 2022-12-07T11:34:43-05:00. Industry Leader For Cattle, Horses, Sheep & Goats The Feed Supplement Brands Built for North America. Regional dynamics, forage types and availability drives our product development. Dealer Locator. Find the New Generation Supplements dealer that is closest to you. ...

Jones Feed Mills has a long history of producing performance enhancing rations and feeding programs for all phases of beef production. Our emphasis is on results, health and economics while considering all available forages and on-farm feed sources. Individual rations are carefully formulated to produce the results you are looking for using ...

2021-9-12·The DA7250 NIR feed and grain analyzer greatly facilitates quality control, paving the road for improved product quality, as well as production savings. It is easy and safe to use assuring improved and simplified day-to-day usage, and offers unique speed, flexibility and accuracy -thereby minimizing out-of-spec production. All feed millers ...

Cost-efficient high feed milling in small diameters. 4 cutting edges. Internal coolant. CoroMill® 745. First choice for production economy 14 cutting edges. Available for 42- and 25-degree lead angle. Internal coolant. CoroMill® MH20. First choice in pocket milling for ISO S, M and P materials.

The micro system was set above a scale which fed to the mixer. The solution: split the micro system into two sections. Install a second scale under one-half of the micro bins. This allowed the micro system to fill batches in less than 4 minutes. The production level jumped to 60 tph, reducing the time needed to make feed by 6 hours per day.

2022-7-8·First utilized in the die and mold industry, high-feed milling is a machining method that pairs shallow depth of cut (DOC) with high feed rate up to 2.0 mm per tooth. This combination maximizes the amount of metal being removed from a part and increases the number of finished parts in a given time. The HFM mechanism is based on the “chip ...

2022-9-7·In summary, high-feed milling is all about chip thinning. You must increase feed rate to compensate for the chip thinning created by the large lead angle, typically 80° to 82.5°. In most cases your feed rate is four to five times faster than standard feed rates utilizing square shoulder or 45° lead milling cutters.

Stating that the Brazilian customer is proud of the new feed plant, Marco Hagen also said they received positive feedback about the feed mill especially because it has high automation level which requires little interference from people, quick start up feature, an easy system to work with and easy adjustment and fine-tuning of parameters.

2019-10-4·“Most of the time we can make significant improvements – one example is that we recently were able to reduce KWh/t usage by 23.2% in a European feed mill.” Securing feed hygiene. The livestock industry has had to deal with several recent epidemics and biosecurity continues to be a focus of processors and consumers alike, and with …

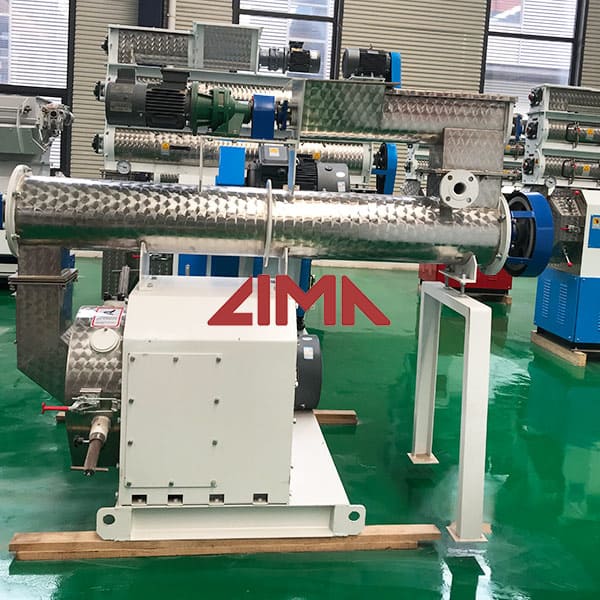

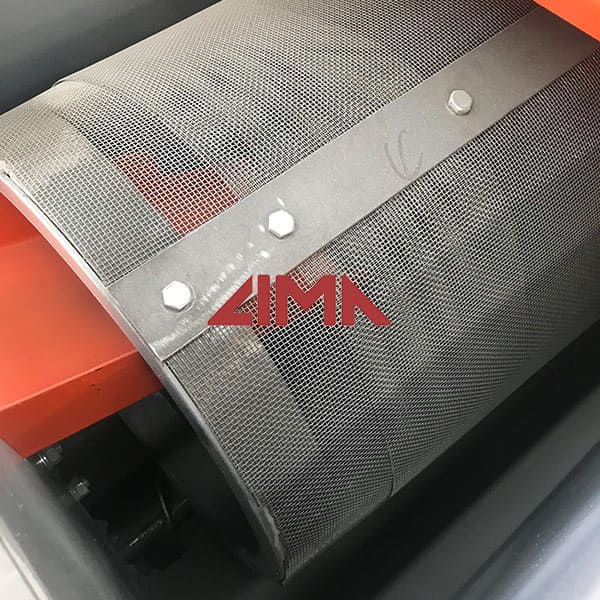

![<h3>20 t/h hour Poultry Feed Mill Plant [Turnkey Project Design]</h3>](/wp-content/themes/lima/load/50/floating fish feed pellet making machine67.jpg)

2022-12-7·Factory Capacity: Produce 20 tons feed pellets per hour (equal to 120,000 ton/year) Application: This feed milling project can process a wide range of livestock and poultry feed (chicken, duck, cattle, sheep, etc). Main Equipment: crushing machine, hammer mill, mixing machine, ring die pellet milling machine, cooling machine, packing machine ...

2021-2-10·The type of (RBV Round Bottom Vie) is more applied among various types of roller mill. Objectives of feed mill operations:-. Helpful to increase the productive value of feed. Increase the consumption rate of feed. After processing the feed become more palatable. The digestibility of feed becomes increases.