Pressed beet pulp. Pressed sugar beet pulp is a product of our production of sugar, rich in nutrients and beet fibres. Pressed beet pulp for direct feeding or as silage is a highly preferred feedstuff for all ruminants. It has a dry substance content of approximately 25 %, which varies depending on the specific sugar factory.

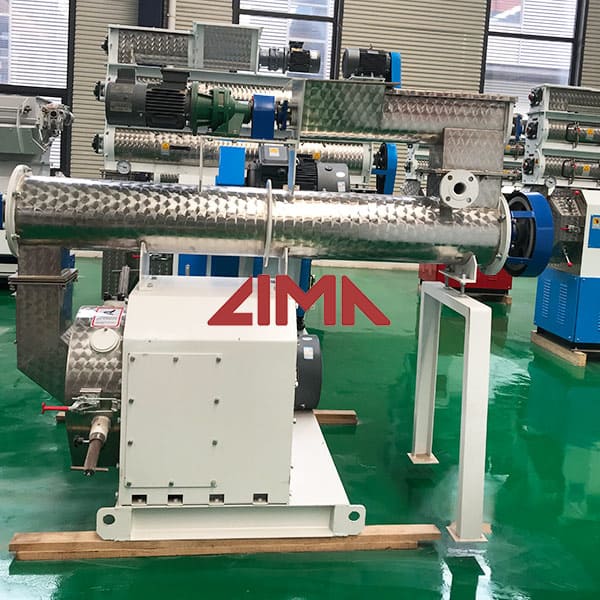

2022-5-9·AMANDUS KAHL. This pellet machine manufacturer is based in Germany and was founded by Amandus Kahl in 1876. AMANDUS KAHL is famous for their flat die presses and has acquired Worldwide subsidiaries and worldwide service . They offer Turn-key factories and plants for feed, biomass, wood, straw, waste tyre recycling etc.

The market is projected to grow from USD 146.6 million in 2021 to USD 185.8 million by 2028 at a CAGR of 3.4% from 2021 to 2028. Beet pulp is the fibrous portion of the sugar beet, left after the sugar and liquid have been removed. It is mechanically pressed, dried, and then pelletized into a 5/16” (8mm) diameter pellet.

2020-12-29·We also supply complete 20t/h capacity poultry chicken feed pellet production line and have many successful poultry chicekn feed mill plant projects around the world. ... Dried beet pulp. Furthermore, the following substances can be used as appetizers in feed pellets: (1)Carob-bean, up to a maximum of 3%. (2)Molasses, up to a maximum of …

![<h3>Citrus Pulp Pellets Market Size, Share, Growth | Report [2028]</h3>](/wp-content/themes/lima/load/50/Chicken feed pellet machine41.jpg)

The global citrus pulp pellets market size was USD 670.1 million in 2020. The market is projected to grow from USD 689.5 million in 2021 to USD 858.4 million by 2028 at a CAGR of 3.18% during the 2021 to 2028 period. The global impact of COVID-19 has been unprecedented and staggering, with witnessing a negative impact on demand across all ...

2021-2-15·However, due to shortage of feed, there has been a gradual shift from traditional feed pattern to compound feed (CF). For livestock it is either in the form of mash, feed block or feed pellets ...

Pressed beet pulp. Pressed sugar beet pulp is a product of our production of sugar, rich in nutrients and beet fibres. Pressed beet pulp for direct feeding or as silage is a highly preferred feedstuff for all ruminants. It has a dry substance content of approximately 25 %, which varies depending on the specific sugar factory.

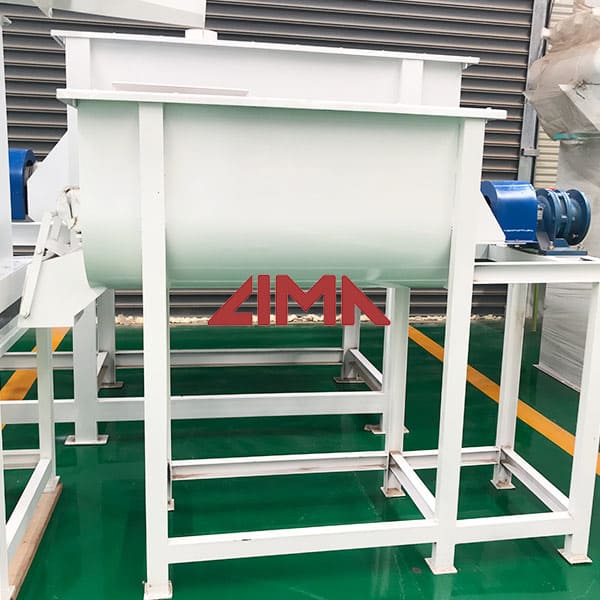

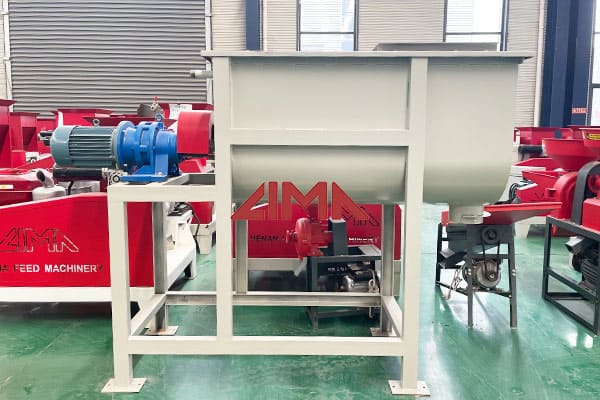

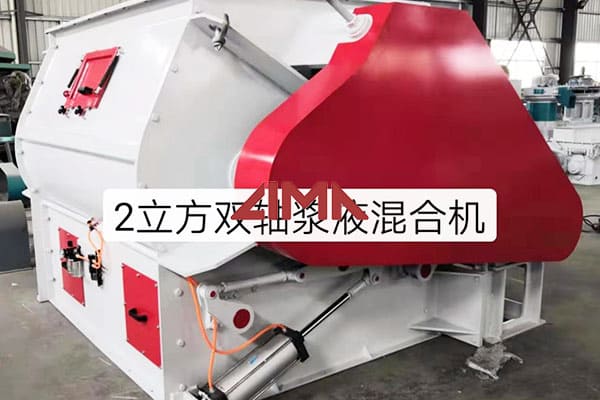

2023-1-30·Operating the livestock feed production equipment line can be relatively easy, but it is critical to adhere to the information manual as well as safety instructions furnished along with the machine. (Read more: Poultry Feed Manufacturing Plant Cost >>) Fulll Equipment of 2TPH Livestock Animal Feed Pellet Mill Plant 1. Mixing Machine 2.

2019-10-18·Feed formulation and viscosity of the feed mash, together with thermal processing, are the most critical factors influencing physical pellet quality. Restricting the addition of ingredients to low viscosity (fat, glycerol, etc..) and applying them in post-production with vacuum technology may increase physical quality of the feed pellets.

The market is projected to grow from USD 146.6 million in 2021 to USD 185.8 million by 2028 at a CAGR of 3.4% from 2021 to 2028. Beet pulp is the fibrous portion of the sugar beet, left after the sugar and liquid have been removed. It is mechanically pressed, dried, and then pelletized into a 5/16” (8mm) diameter pellet.

2021-2-15·However, due to shortage of feed, there has been a gradual shift from traditional feed pattern to compound feed (CF). For livestock it is either in the form of mash, feed block or feed pellets ...