2007-6-8·Grinding of Feedstuffs. Grinding is a major function of feed manufacturing and is by far the most common method of feed processing. It is also the most cheapest and simple process and results in a substantial reduction in particle size and exposure of much more surface area to action of chemicals as well as to the digestive juices.

2017-1-16·Once the feed has been formulated and mixed, it will go through the final steps in the manufacturing process before animal consumption. Before being packaged, the feed goes through a pelleting process and just like human food, animal feed can have a variety of textures such as pelleted, flaked, crumbled, meal or extruded.

2018-6-20·The process of manufacturing animal feed is a means whereby raw materials of widely ranging. physical, chemical and nutritional composition can be converted into a homogenous mixture. suitable for producing a desired nutritional response in the animal to which the mixture is fed. The process is basically a physical one and chemical …

2022-8-18·Animal feed. Animal feed is the food grown or developed for livestock and poultry. Animal feeds are produced by precisely choosing and blending ingredients to provide highly nutritional diets that both maintain the health of the animals and increase the quality of such end products as milk, meat, or eggs. Chemical analysis, experimentation, …

2022-4-19·Animal feed produced from food waste (e.g., food dregs and expired food items in the process of food production, cooking, and selling) is called “eco-feed” in Japan. The production of eco-feed can not only contribute to the reduction of food waste, but can also help overcome the low rate of food self-sufficiency in Japan (Liu et al. 2016 ...

Annual Feed Production (metric tons): 20,000. Revenue: USD 19.72 billion. Industry: Animal Feed, Food Processing. 3. Cargill. Cargill ranks 3 rd on this list of the top 10 largest animal feed manufacturers in the world in 2022. Cargill is present in more than 66 countries and has a workforce of over 136,000 employees.

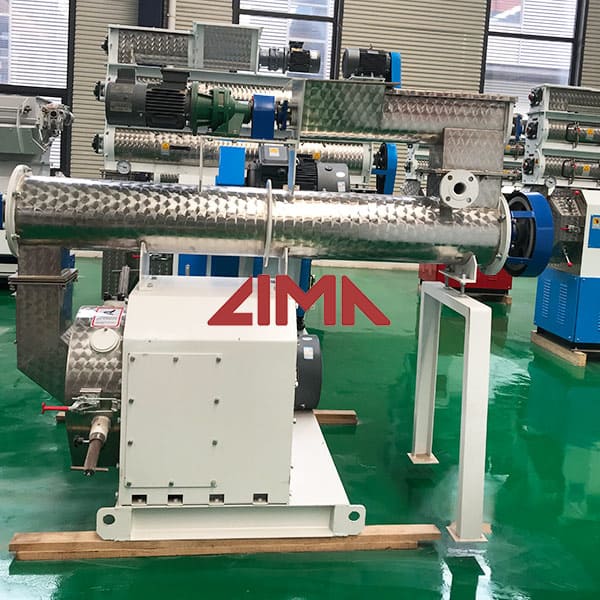

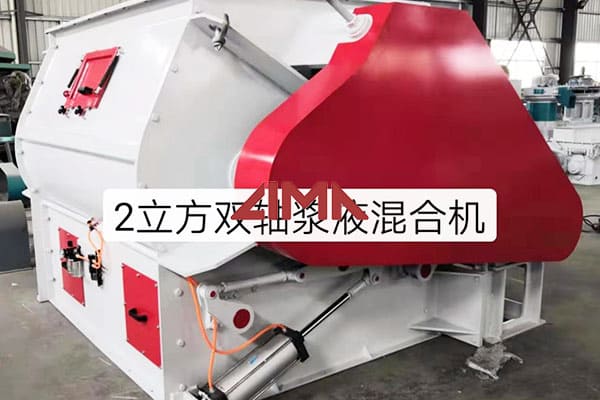

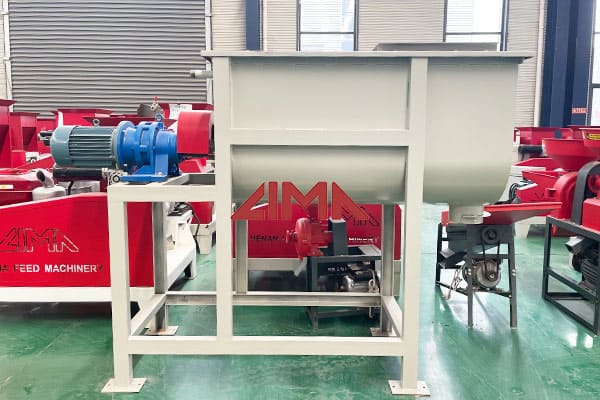

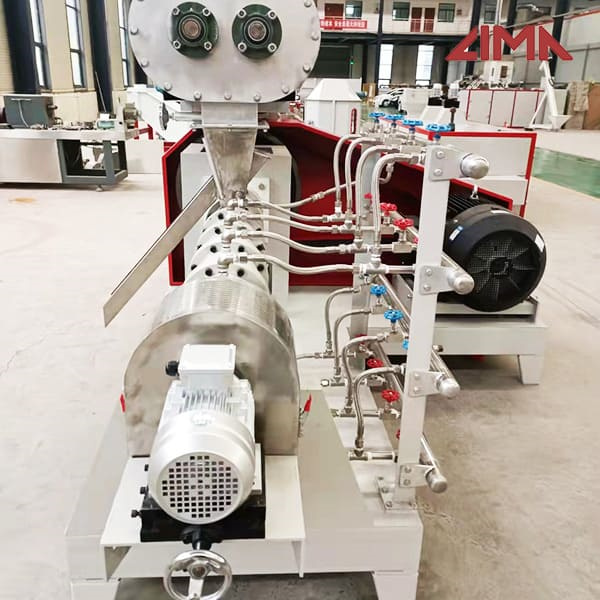

2021-4-16·Design 1: Animal Feed Manufacturing Process. Raw materials reception → cleaning and removal of impurities → crushing → batching → mixing → pelleting → sieving & cooling → feed pellets packaging. This includes a series of steps like removal of impurities and cleaning, crushing, batching, mixing, pelletizing and sieving and cooling.

2023-1-26·Document Category: Feed & Feed Ingredient Manufacturing Committee. 2015 Joint FAO/WHO Expert Meeting on Hazards Associated with Animal Feed Executive Summary January 26, 2023. By philosophy2 2016 Model Emergency Response Document January 26, 2023. By philosophy2

2023-2-6·3. Addresses labor shortages, safety concerns. Automatic roller adjustment helps create a safer work atmosphere. “Your operators now have less hands-on activity with the pellet mill and the die cavity,” he said. “The more that we can keep their hands out of that machine, the safer your operation is going to be.”.

Four basic steps to producing animal food. Feed mills receive raw ingredients from suppliers. Upon arrival, the ingredients are weighed, tested and analyzed for various nutrients and to ensure their quality and safety. Nutritionists work side-by-side with scientists to formulate nutritionally sound and balanced diets for livestock, poultry ...

2007-6-8·Grinding of Feedstuffs. Grinding is a major function of feed manufacturing and is by far the most common method of feed processing. It is also the most cheapest and simple process and results in a substantial reduction in particle size and exposure of much more surface area to action of chemicals as well as to the digestive juices.

The process of manufacturing animal feed is a means whereby raw materials of widely ranging physical, chemical and nutritional composition can be converted into a homogenous mixture suitable for producing a desired nutritional response in the animal to which the mixture is fed. The process is basically a physical one and chemical changes are few.

2022-5-29·Animal feed manufacturing process of the animal feed factory project. Note: There are two high-end poultry and livestock feed production lines, one high-end ruminant feed production line, and the process flow of the three animal feed pelleting lines is the same. Raw materials preparation.

2019-12-18·The diameter of the final feed pellets can be 2 to 8 mm. This is a multi-functional feed pellet making machine for the processing various feed pellets for poultry, livestock and animal. Feed manufacturing process flow chart. First, remove impurities such as iron chips and stones from raw materials.

2023-1-26·Document Category: Feed & Feed Ingredient Manufacturing Committee. 2015 Joint FAO/WHO Expert Meeting on Hazards Associated with Animal Feed Executive Summary January 26, 2023. By philosophy2 2016 Model Emergency Response Document January 26, 2023. By philosophy2

2023-2-6·3. Addresses labor shortages, safety concerns. Automatic roller adjustment helps create a safer work atmosphere. “Your operators now have less hands-on activity with the pellet mill and the die cavity,” he said. “The more that we can keep their hands out of that machine, the safer your operation is going to be.”.

17 ·Type: Feed Pellet Production Line Processing Object: Corn, Maize, Wheat, Bean, Grain etc Processing Technics: Crushing-before-Mixing Screen Mesh: With Screen Mesh Grinding Equipment Type: Feed Hammer Mill Pellet Mill Type: Flat Die Pelletizer