2023-2-6·Shell: The shell of the steam corn flake, the protective cover plate and the front and rear upper and lower door plates are all made of stainless steel, the whole plate is laser blanking, the machine and seat are designed in an integrated way, and the part contacting the material is 304 stainless steels. Hydraulic station: energy-saving air …

Quality standards for steam-flaked corn include measurements of flake thickness, flake density, starch solubility, and enzyme reactivity. Flake density, the most common quality standard, closely associated with starch solubility (r2 = 0.87) and enzyme reactivity (r2 = 0.79), still explains only 63% of the variability in percentage fecal starch ...

Roskamp Champion steam chambers are designed and sized to specifically fit your unique steam-flaking application. Our one-of-a-kind steam inlet design ensures uniform flow and low-velocity, high-volume steam addition. The vertical, inversely tapered design allows for grain expansion, and the smooth, obstruction-free interior allows for uniform ...

The corn flakes production line takes corn flour as the main raw material for production. Through raw materials mixing, twin screw extruder, high temperature extrusion, flaking, and pre-drying with a multi-layer mesh belt dryer, sugars spraying (such as maltose can be added through a sugar spraying and mixing system), and high temperature baking, …

2019-3-5·January 23, 2019. Mohamad; The moisture content entering the flaking mill should be close to 18% and make sure you have enough residence time in the steam chest in order to hydrolyze the starches. You must be wasting a lot of energy (in form of steam) by trying to transfer the heat into the corn by having an oversized steam chest.

2022-11-5·With years of researching and studying the corn flakes cereal making machine technology abroad and invested millions in the R&D of the production technology of the corn flakes cereal making machine, Heshan Machinery Co., Ltd., one of the leading providers of China's corn flakes cereal making machine, has successfully developed the …

2023-1-27·Maize (Makai) Flake Machinery By Heavy Machines. Get latest price. ... Ce Certification Corn Flakes Extruder Machine Breakfast Cereal Production Line Capacity: 150-500kg Kilogram(Kg) 6500 - 35000 USD ($) Get ... We are engaged in exporting and supplying excellent quality Corn Flake Packing Machine to our valuable clients. DSC- D …

Small Scale Corn Flakes Production Line, Corn Flakes Processing Line, Machine to Make Corn Flakes with CE Certification ISO9001 $50,000 - $180,000 / Set Min.Order: 1 Sets

2023-2-6·Shell: The shell of the steam corn flake, the protective cover plate and the front and rear upper and lower door plates are all made of stainless steel, the whole plate is laser blanking, the machine and seat are designed in an integrated way, and the part contacting the material is 304 stainless steels. Hydraulic station: energy-saving air …

2022-11-2·After-sales Service: 1 Year Warranty: 1 Year (Expect Spare Parts) Type: Pressing Machines Application: Corn/Maize Voltage: 380V Appearance: Horizontal

Small Scale Corn Flakes Production Line, Corn Flakes Processing Line, Machine to Make Corn Flakes with CE Certification ISO9001 $50,000 - $180,000 / Set Min.Order: 1 Sets

2002-6-1·Steam chests should be designed to allow a steaming time of at least 30 min at maximum roller mill capacity producing a flake of 0.31 kg/L (24 lb/bushel). As little as 5% moisture uptake during ...

Breakfast Cereal Production Line Corn Flakes Machine crispy toasted maize flakes Corn flakes making machine / set. 1 set (Min Order) 13YRS. CN. Supplier > 5.0 (6) | "good business" ... Instant chocolate coco crispy breakfast cereal machine small corn flake making machine / set. 1 set (Min Order) 10YRS. CN. Supplier >

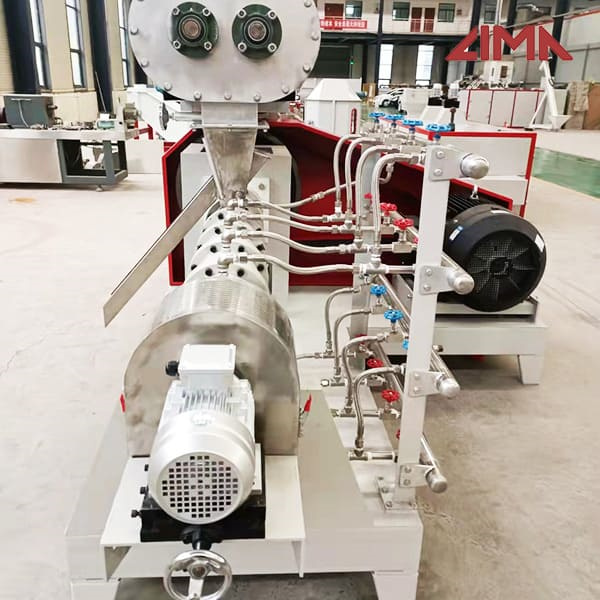

Model 600 Fully Automatic Hydraulic Steam Corn Tablet/press mill machine. Main technical parameters. 1. Power of main drive motor: 30KW (two sets), feeding motor 0 55KW (one sets). 2. Blank standard: 1.5-2.0 mm. 3. Whole machine weight: about 6.5T. It adopts fully enclosed structure, square bearing seat and protective cover made of SS304 ...

2020-7-31·In addition, to reduce corn flake thickness, the production costs of gas and electricity increased owing to overloading of the rolls . Reinhardt et al. reported that, compared to the corn flake density was 361 g/L, production cost per ton of corn flakes increased by 26.9% and 67.5% at 322 and 238 g/L, respectively. Furthermore, as the …

The corn flakes production line takes corn flour as the main raw material for production. Through raw materials mixing, twin screw extruder, high temperature extrusion, flaking, and pre-drying with a multi-layer mesh belt dryer, sugars spraying (such as maltose can be added through a sugar spraying and mixing system), and high temperature baking, …

2019-1-18·Experimental diets contained either finely ground corn (FGC) or steam-flaked corn (SFC) based on either low protein (LP, 14.8%) or high protein (HP, 16.2%) content. The way of processing is explained in the box below. Diets contained 40% corn either finely ground or steam-flaked. The forage to concentrate ratio was 40:60 on a DM …