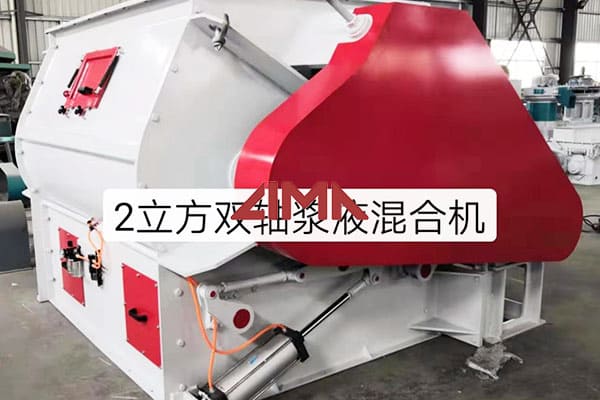

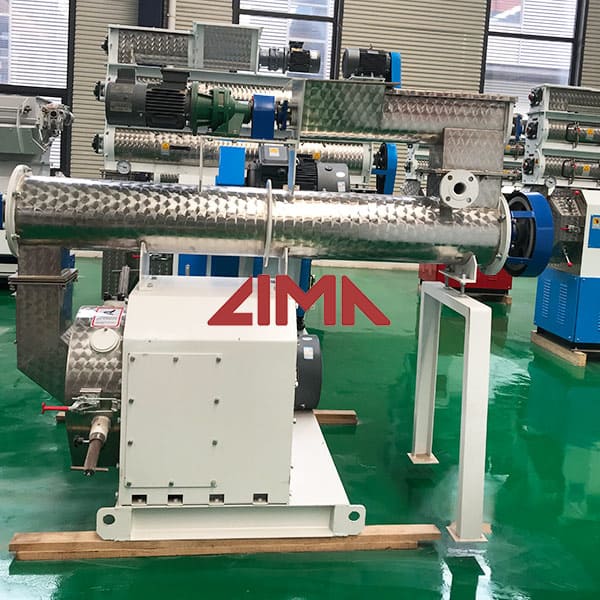

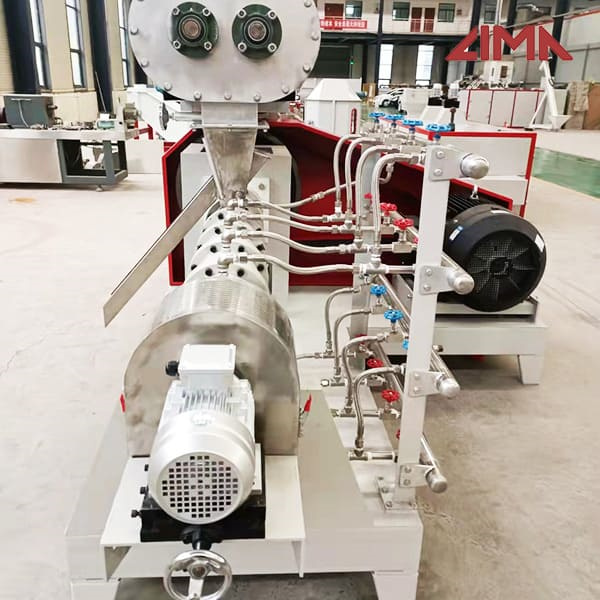

2 ·Project Name: Mini Feed Mill Plant Production Output: 1 ton per hour Application: Specially designed for sheep and cattle feed processing production. Related Product: Small Feed Pellet Line for 800-1100kg/h Production Sheep & Cattle Feed Mill Plant Photo Display. The feed mill plant unit includes equipment of grinding, mixing, pelletizing and cooling. …

2018-6-3·Pits can be flushed with small amounts (100 lbs) of low risk ingredients at the end of each day. Ground corn (100 lbs) containing from 0.5% to 1.0% organic acids (propionic, acetic, or formic) can also be used periodically for sanitation to minimize the risk of contamination.

2019-10-4·Livestock producers, whether poultry, dairy, aqua or even swine operate in highly competitive environments. Efficiency savings across the supply chain can yield great results from a relatively low investment. One area often ripe for improvement is in feed mills, where adjusting operations, settings or processes can yield huge savings.

The National Biosecurity Manual for Feed Mills was produced by the Stock Feed Manufacturers’ Council of Australia (SFMCA). The manual is a key tool for producers interested in implementing and performing sound biosecurity practices on their property. It was produced to assist feed mills in translating biosecurity practices into operating ...

2021-2-8·In the first half of 2020, dust generated in food processing operations were responsible for 41 fires, 8 explosions and 11 injuries globally, according to the 2020 Mid-Year Combustible Dust Incident Report. That’s 40.8% of all recorded incidents. Since 2017, agricultural activity and food production were the cause of 33% to 45% of annual ...

2017-10-23·mills have intrinsic cooling due to compressed air expan-sion in the body of the mill. With the help of sweeping air, hammer mills may also be able to process materials with low melting points for coarse grinding applications. Explosibility. The risk of dust explosions must be taken into account when a material is ground very fine in a milling

2018-6-3·Pits can be flushed with small amounts (100 lbs) of low risk ingredients at the end of each day. Ground corn (100 lbs) containing from 0.5% to 1.0% organic acids (propionic, acetic, or formic) can also be used periodically for sanitation to minimize the risk of contamination.

2022-7-6·The risk is very low, but the revenue of that loan is also low. Perhaps an investment in the animal feed sector brings a return of 12%, but the risk to achieve this is obviously greater. The financial side of a project consists of the investment (capital expenditure; Capex), revenue, operational costs (operational expenditure; Opex) and rest ...

China Poultry Feed Plant manufacturers - Select 2023 high quality Poultry Feed Plant products in best price from certified Chinese Feed Machine, Agriculture Machine suppliers, wholesalers and factory on Made-in-China.com ... Farm Use 100-1000kg Pellet Mill Cattle Sheep Pig Animal Small Chicken Feed Poultry Feed Mill Plant. US$ 2450-9360 / Set ...

2022-8-22·A strong quality control programme is the foundation for establishing effective mycotoxin management at the feed mill. Such a programme helps ensure that all raw materials entering the facility are quality tested based on several factors and strategies, including storage, processing and finished feed storage. Research was carried out to …

Identify the top automation benefits your mill can achieve with Repete’s modern FLX Control System. Imagine a highly automated, much more intelligent plant control system. The latest technology and functionality. Built-in data redundancy and a higher level of recovery. This only begins to describe your FLX Plant Automation System Experience.

2022-3-18·ATTALLA, Alabama — Representatives of Koch Foods joined state and local leaders in Etowah County on Thursday to formally open the company’s state-of-the-art grain storage and distribution facility in Attalla. Koch Foods (pronounced “Cook”) said the new poultry feed-mill will create 32 new jobs with an annual payroll of $1 million.

2021-2-8·In the first half of 2020, dust generated in food processing operations were responsible for 41 fires, 8 explosions and 11 injuries globally, according to the 2020 Mid-Year Combustible Dust Incident Report. That’s 40.8% of all recorded incidents. Since 2017, agricultural activity and food production were the cause of 33% to 45% of annual ...

16 ·After-sales Service: Spare Parts Available with Competitive Price Type: Pellet Mill Processing Object: Corn, Wheat, Sota Beans, etc. Processing Technics: Feed Pellet Machine Screen Mesh: 2mm,4mm,6mm,8mm,12mm Grinding Equipment Type: Roll Crusher