ANDRITZ offers unique, high-capacity extrusion lines for the production of all kinds of feed for fish and shell fish. The ANDRITZ extruders ensure that the feed has the right physical properties – giving it the correct sinking attributes according to where in the water the feed should be accessed. ANDRITZ single screw extruders represent ...

![<h3>[PDF] DESIGN AND CONSTRUCTION OF A FISH FEED …</h3>](/wp-content/themes/lima/load/50/Chicken feed pellet machine51.jpg)

2016-8-1·The aim of this project is to design and fabricate a fish feed extruder with improved qualities and affordable cost using locally sourced materials to aid the production of extruded feeds by local ...

1 ·The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

2016-1-1·Based on the available information, annual aquafeed production is around 30 million tonnes ().Similarly in Malaysia, shrimp feed production in 2013 is estimated to be less than 50% of production capacity and even at peak production of 110,000 tonnes in 2010, it was 84% of capacity. In Thailand, Wilson (2013) indicated a usage rate of only …

2004-4-1·Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

2018-10-11·The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

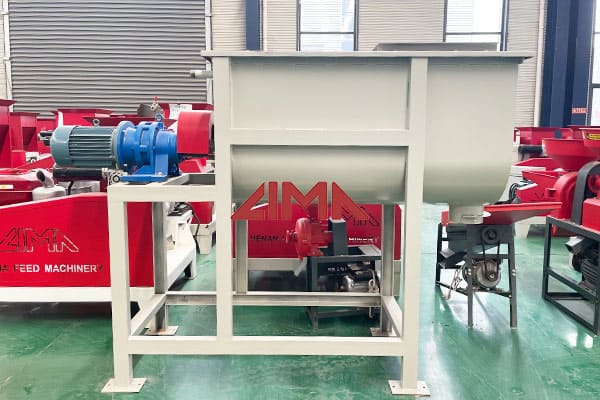

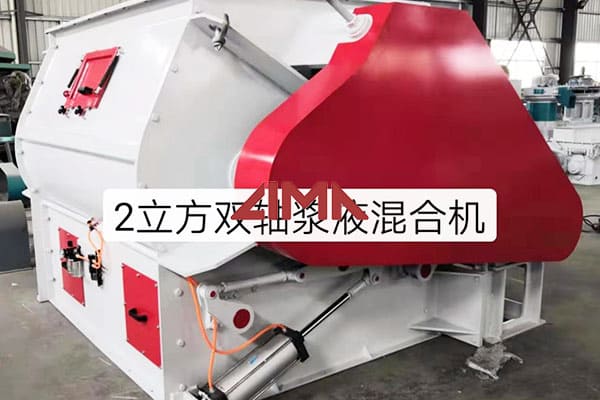

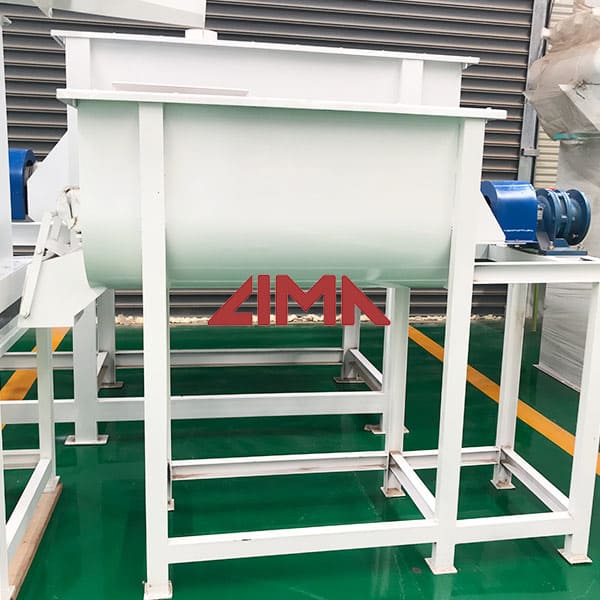

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

Due to its low-power consumption, the commercially available Tmote Sky wireless sensing unit was chosen for this study. 17 The Tmote Sky uses the low-power 16-bit Texas Instruments microprocessor, MSP430F1611, which provides 10 kB of RAM and 48 kB of FLASH memory, while running the TinyOS operating system.

2023-2-14·Fish meal factory, Bressay. Manufactured feeds are an important part of modern commercial aquaculture, providing the balanced nutrition needed by farmed fish. The feeds, in the form of granules or pellets, provide the nutrition in a stable and concentrated form, enabling the fish to feed efficiently and grow to their full potential.

The new extruder features AMANDUS KAHL stop bolt technology for ideal mixing and venting in the first cylinder section. Special process sections for compaction, cooking and kneading provide a high degree of flexibility and a wide range of setting options for processing feed. Exchangeable screw elements ensure perfect adaptation to different ...

Capture fisheries production should experience modest growth (+3.6% by 2030), with some fluctuations in El Niño years (2022 and 2027), which will also negatively affect production of fishmeal and fish oil. In 2030, world production of fishmeal is projected to reach 5.8 Mt, increasing 0.9% p.a. relative to the average 2018-2020 level, while ...

![<h3>[PDF] DESIGN AND CONSTRUCTION OF A FISH FEED …</h3>](/wp-content/themes/lima/load/50/Chicken feed pellet machine75.jpg)

2016-8-1·The aim of this project is to design and fabricate a fish feed extruder with improved qualities and affordable cost using locally sourced materials to aid the production of extruded feeds by local ...

2016-1-1·Based on the available information, annual aquafeed production is around 30 million tonnes ().Similarly in Malaysia, shrimp feed production in 2013 is estimated to be less than 50% of production capacity and even at peak production of 110,000 tonnes in 2010, it was 84% of capacity. In Thailand, Wilson (2013) indicated a usage rate of only …

In many cases, modernization of the extruder drive already leads to significantly better utilization of the energy input and thus to a reduction in energy consumption. In addition, each individual process step in production and their interrelationships can provide potential for reducing energy consumption. For example, it is possible to recover ...

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

2011-5-20·Extruder Motor Load KW) 300 30. Water Dried Off 15% 22%. The cold extruded product runs off the extruder at higher moisture than the hot extruded product, but it is much cheaper to dry off the extra 7% water than it is to raise the 7% steam needed for the hot extruded product and look at the difference in motor power.