Based on performance of feedlot cattle, steam flaking increases the value of corn by 18%, considerably more than is suggested by tabular values. ... Flaking corn: processing mechanics, quality standards, and impacts on energy availability and performance of feedlot cattle J Anim Sci. 2002 May;80(5):1145-56. doi: 10.2527/2002.8051145x.

2015-8-20·An Effective Solution to this problem is the calculation of machine utilization in the manufacturing industry. Overall Equipment Effectiveness optimizes the process and gives us the definite ...

2020-10-13·corn. A list of initial equipment and cost to roll corn is in Table 1. For the 5,000-head capacity feedlot, a rollermill (17.8-cm × 45.7-cm rolls with a 10-hp motor) that was capa-ble of processing 15.4 t of corn (DM basis)/h was used. For the 20,000-head capacity feedlot, a rollermill (22.8-cm × 91.4-cm rolls with a 30-hp motor) that was ...

2022-8-18·30 Run Hours/40 Available Hours x 100 = 71% Machine Utilization. In another scenario, in a 24/7 facility, the equipment would be scheduled with no idle hours, and the total available hours would be 168. If the machine runs 85 hours, the machine utilization rate would be 51%. 85 Run Hours/168 Available Hours x 100 = 51% Machine …

2017-11-8·The fourth clamping was again assigned to machines - Machine_1 and Machine_2. Machine_3 then performs the fifth component manufacturing process in sequence. The final operation is run on Machines ...

2023-2-16·Ground, 2. corn root stubble, 3. soil particles factory, 4. fertiliz particles factory, 5. corn-overlapped strip fertilizer spreader. Schematic diagram of fertilizer monitoring area.

Anaerobic digestion technology is regarded as the most ideal technology for the treatment of a distiller in terms of environmental protection, resource utilization, and cost. However, there are some limitations to this process, the most prominent of which is microbial activity. The purpose of this paper is to provide a critical review of the microorganisms involved in the …

2021-11-11·1.3.1 Particle model. In this study,cornstalks,including cornstalk branches and leaves,were crushed using a dual-roller crushing device for raw materials.Random sampling revealed that more than 90% of the crushed cornstalks were less than 50 mm in length with a moisture content of 34.68%.A vernier caliper was used to measure the …

2002-6-1·In addition to improving the digestibility of corn, steam flaking also reduces methane energy loss by as much as 30% (Johnson et al., 1968; Zinn, 1987; Zinn et

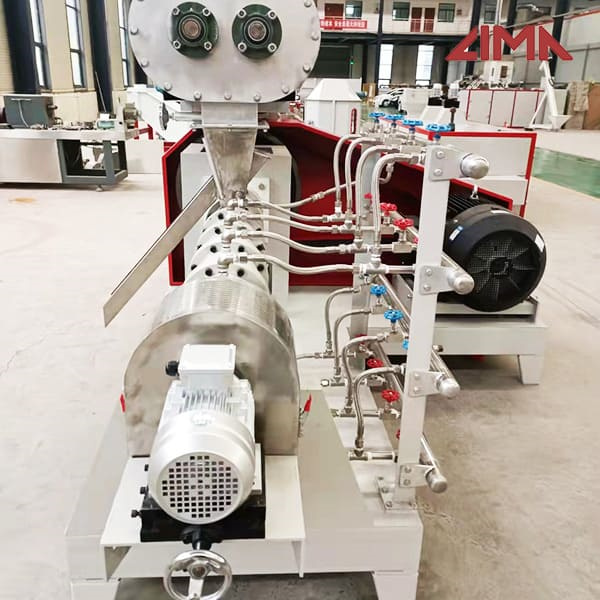

2023-2-18·The Flake Master™ Flaking Roll provides consistent processing of a wide range of flakes such as corn, bran and multigrain cereals. Learn more about this. Share. ... Machines with 975 and 1,275mm roll-widths offer outputs of 1,000 and 1,750 kg/hour respectively, based on cornflakes before drying and toasting. ...

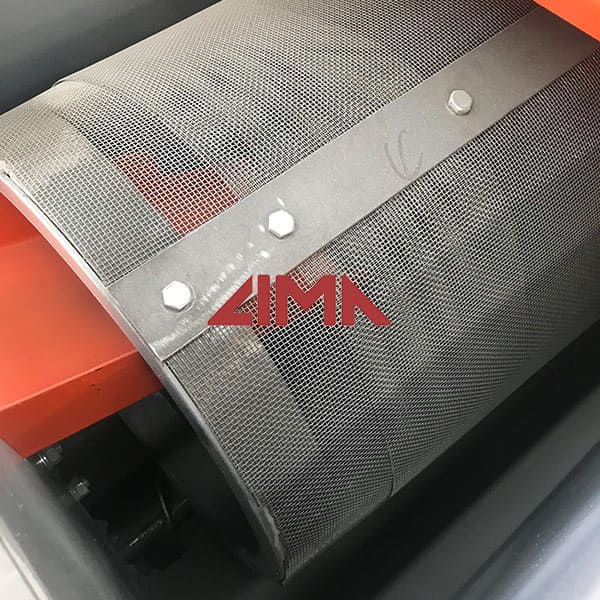

The flaker itself consists of a single pair of smooth rolls with a small operational clearance between the two. The cracks enter the flaker from a feed hopper; they then pass between the flaker mill rolls where they are pressed flat. This process is known as flaking. For soybeans, this is the final preparation stage prior to solvent extraction.

2018-4-24·Overall Equipment Effectiveness. It is a way to monitor and improve the efficiency of the manufacturing process.OEE is one of the ways to optimize the performance of the existing equipment and gives ability to measure the machines for productivity improvement. LITERATURE REVIEW. Overall equipment effectiveness (OEE) is a …

The capacity of corn flakes processing plant is to produce 1200 MT of corn flakes per year. During fist year only 50% capacity will be utilized, second year 80% and from third year onwards 90% of total capacity will be utilized. Yield and Production At 90 % capacity utilization around 1200 MT of corn flakes per year will be produced.

2023-2-16·Ground, 2. corn root stubble, 3. soil particles factory, 4. fertiliz particles factory, 5. corn-overlapped strip fertilizer spreader. Schematic diagram of fertilizer monitoring area.

2016-1-1·Grading: This is the processing of bulk farm produce to clean grain through grading and cleaning by a cleaner-cum-grading machine.This machine grades grain based on the size of the grain and separates it into three sizes (): bigger size, medium size, and small size and it also separates unwanted particles.The grain thus separated is collected …

Anaerobic digestion technology is regarded as the most ideal technology for the treatment of a distiller in terms of environmental protection, resource utilization, and cost. However, there are some limitations to this process, the most prominent of which is microbial activity. The purpose of this paper is to provide a critical review of the microorganisms involved in the …

2021-11-11·1.3.1 Particle model. In this study,cornstalks,including cornstalk branches and leaves,were crushed using a dual-roller crushing device for raw materials.Random sampling revealed that more than 90% of the crushed cornstalks were less than 50 mm in length with a moisture content of 34.68%.A vernier caliper was used to measure the …