Despite the decline in the proportion of world capture fisheries production reduced to fishmeal and fish oil, the production of fishmeal and fish oil (in product weight) produced from whole fish is projected to increase in 2029 by 5.6% and 9.2%, respectively, compared to the base period.

2020-7-30·Both fishmeal and animal oil are employed as high protein ingredients within the feeds given to farmland animals and farmed fishes. ... Production of fishmeal & fish oil has remained comparatively ...

2021-2-8·2006a). Most notable have been the increases in production in China and Chile. Fishmeal and fish oil are important feed ingredients in aquaculture, and by 2003 their consumption by the sector had increased to 2.94 million and 0.80 million tonnes, representing 53.2 and 86.8 percent of global production, respectively (Tacon, Hasan

2020-3-28·Purpose Fish waste was studied as a raw material for the simultaneous production of protein hydrolysates, collagen and fish oil. Enzymatic hydrolysis was selected for recovering these by-products with high value-added. Methods Alcalase 2.4 L was used to hydrolyze fish waste in a batch reactor under controlled conditions (180 min, 50 °C and …

IFFO producers are committed to undertake this production with minimal change in nutritional value. Raw material is handled rapidly and mainly chilled to prevent spoilage. Standard fishmeal: they are referred to as "fair average quality" (FAQ) when the drying phase is direct hot air, and are ideal for poultry, ruminants and omnivorous fish.

The Peruvian fishmeal and fish oil producer Copeinca has illustrated how the value chain in the industry is formed. The production process can roughly be described in three steps: First the fish is inspected, cleaned and cooked at about 95 ° Celsius. This process helps sterilize the fish as well as separate out proteins and oils.

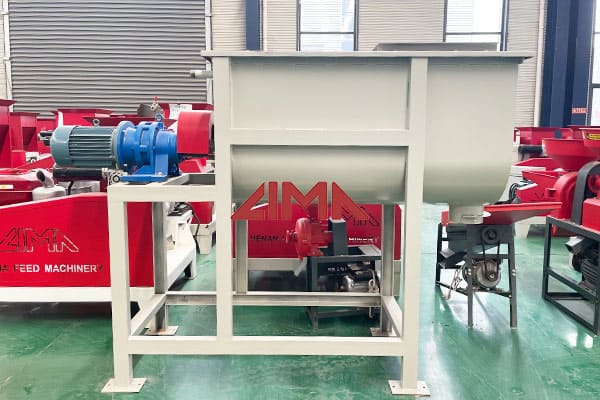

The fishmeal thus produced is stored in a well maintained godown. Most of the equipments for the production of fishmeal are manufactured and imported from China. The conveyors that are used in the production line are all Stainless steel materials. The shelf life of the fishmeal is increased by adding suitable antioxidant in a recommended dosage.

The oil and the water mixture separated goes into a centrifuge where fish oil is separated. The fish cake from the screw press goes into a steam drier. The dried meal is than pulverized and cooled. The fine powder is than filled in High-density polyethylene bags. The Filtered fish oil is packed in steel/plastic drums of 200 litres.

23 ·FOF (Fishmeal, oil and feed) The outlook of fishmeal and fish oil production is dependent on the availability of raw materials. The ICES 2023 recommendation for blue whiting is 1,360 thousand tonnes, which is an 81% increase from the recommendation for 2022. In 2023 Bakkafrost expects similar production volumes of fishmeal and fish oil as …

2021-11-22·High-quality fishmeal is 60–72% crude protein 27, and methanotrophic biomass is 67–81% crude protein 12. This analysis thus defines the SCP product as the organic biomass of the dried cell ...

2019-12-17·Aquaculture producers have successfully utilised plant-based ingredients, like soy and soy-based proteins, for many years, but more recently their search for fishmeal and fish oil replacements has veered towards microalgae, single-cell organisms and insects. Global fisheries and aquaculture production, 1976 to 2013, in metric tons per year.

2021-1-20·Request PDF | Efficiency of fishmeal and fish oil processing of different pelagic fish species: Identification of processing steps for potential optimization toward protein production for human ...

2021-2-8·2006a). Most notable have been the increases in production in China and Chile. Fishmeal and fish oil are important feed ingredients in aquaculture, and by 2003 their consumption by the sector had increased to 2.94 million and 0.80 million tonnes, representing 53.2 and 86.8 percent of global production, respectively (Tacon, Hasan

2022-12-15·The present study evaluated the effects of replacing fishmeal protein by Chlorella vulgaris meal and fish oil by a blend of Schizochytrium sp. and Microchloropsis gaditana on growth, feed utilization, muscle fatty acid composition and liver histology of Sparus aurata.Fish were fed twice a day for 12 weeks, six isonitrogenous (52% CP) and …

The Peruvian fishmeal and fish oil producer Copeinca has illustrated how the value chain in the industry is formed. The production process can roughly be described in three steps: First the fish is inspected, cleaned and cooked at about 95 ° Celsius. This process helps sterilize the fish as well as separate out proteins and oils.

Fishmeal. Fishmeal is a dried marine powder. Danish fishmeal consists in average of 71% fish protein and 8 % fish oil. The rest is minerals and water. Fishmeal is an important and very digestible fish protein and fish oil ingredient in feeds and is used for the production of feed for aquaculture and agriculture.

Here you can find the related products in Fishmeal And Fish Oil Production Line, we are professional manufacturer of Fishmeal And Fish Oil Production Line, Fish Oil System, Fishmeal Transport Machine, Fish Meal Fish Oil Machine.We focused on international export product development, production and sales. We have improved quality control processes …