2021-6-8·Tyson Foods owns more than 32 animal feed-producing mills, providing fodder for chicken, pig, and other cattle worldwide. The company's major animal feed sales markets include Central America, Brazil, Mexico, Canada, the European Union, Japan, the Middle East, South Korea, and Taiwan. 4. Alltech.

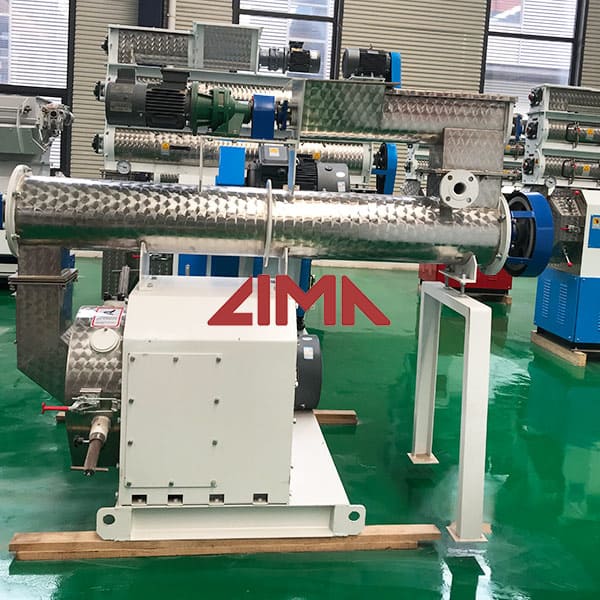

2022-12-29·The pelleted feed manufacturing process has undergone a significant evolution in recent decades due to the demand for higher standards of physical quality, nutritional value and microbiological hygiene, as well as greater flexibility in the incorporation of new and varied raw materials.The digital age in feed industry is becoming increasingly …

The animal feed processing project takes 2 months from civil construction to production. The animal feed manufacturing plant cost is about 50000-120000USD. This animal feed production project has a fixed workforce of 10 people, no board and lodging, three shifts, 8 hours per shift, 250 days of work per year.

2017-6-12·This prevents selective eating of the animals, ensuring each animal will consume a balanced diet. Pelleting of the feed also improves the logistic properties of the compounded feed. The pellets have a higher density then feed mash, enabling more feed to be transported in the same shipment. Furthermore, the dust formation in the product …

2022-1-25·Credit: Adobe Stock. 01.25.2022. By Arvin Donley. LEXINGTON, KENTUCKY, US — Global feed production increased 2.3% in 2021, according to the 11th annual Alltech feed survey, released on Jan. 25. The survey, which includes data from more than 140 countries and more than 28,000 feed mills, found that international feed …

2021-9-12·The DA7250 NIR feed and grain analyzer greatly facilitates quality control, paving the road for improved product quality, as well as production savings. It is easy and safe to use assuring improved and simplified day-to-day usage, and offers unique speed, flexibility and accuracy -thereby minimizing out-of-spec production. All feed millers ...

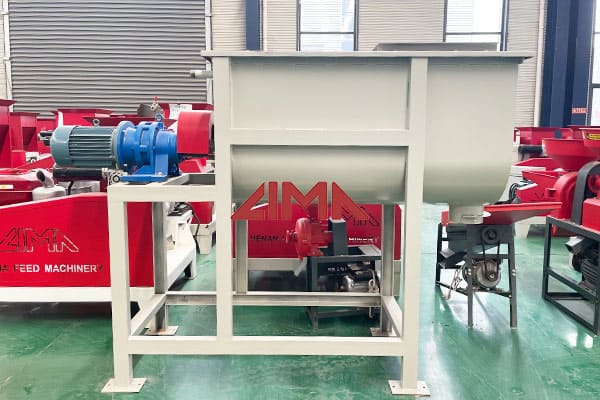

15 ·Type: Mixing Equipment Processing Object: Mixed Feed Processing Technics: Crushing-before-Mixing Condition: New Applicable Materials Shape: Powder Suitable: Manufacturing Plant, Farms, Feed Mill

2021-2-15·However, due to shortage of feed, there has been a gradual shift from traditional feed pattern to compound feed (CF). For livestock it is either in the form of mash, feed block or feed pellets ...

2021-12-27·Construction content and scale of the 125tph full automatic animal feed processing plant——animal feed processing plant project proposal. The 125 tons per hour animal feed processing plant area where the project is located covers an area of 26,600 m², with a construction area of 20,000 m². The large animal feed processing plant design and …

2021-1-26·It comprises global data, collected from more than 140 countries and more than 28,000 feed mills. “Fortified by a decade of documentation and research, it is the strongest evaluation of compound feed production and prices in the industry and is the most complete data source of its kind,” says the animal health and nutrition player.

2021-5-27·A higher number of tons per run improves the mill’s efficiency by minimizing the number of times the operator switches to a different feed type either in the mixing or pelleting process. For operations without a pelleting line, changeovers can cost the operator approximately 5 minutes depending on the design of the system and the designated ...

2021-4-26·Even worse, some molds release toxins harm animals’ health and performance. On the other hand, too little moisture in feed has a negative impact on feed digestibility and pellet durability, increasing the level of fines, process loss and energy consumption, while decreasing press yield (Moritz et al., 2002).

The animal feed processing project takes 2 months from civil construction to production. The animal feed manufacturing plant cost is about 50000-120000USD. This animal feed production project has a fixed workforce of 10 people, no board and lodging, three shifts, 8 hours per shift, 250 days of work per year.

2022-8-22·A strong quality control programme is the foundation for establishing effective mycotoxin management at the feed mill. Such a programme helps ensure that all raw materials entering the facility are quality tested based on several factors and strategies, including storage, processing and finished feed storage. Research was carried out to …

2021-2-8·in feed mills and plants producing premixes and mixed feed according to the protocols of the Swiss feed control authorities (ALP, 2004). The implementation of feed bans and the manufacturing process itself are described in separate chapters in this course manual. 2.1. working areas and production equipment

15 ·Type: Mixing Equipment Processing Object: Mixed Feed Processing Technics: Crushing-before-Mixing Condition: New Applicable Materials Shape: Powder Suitable: Manufacturing Plant, Farms, Feed Mill

2018-1-26·International feed tonnage has exceeded 1 billion metric tons for the second consecutive year, with a total of 1.07 billion metric tons of feed produced in 2017. This is according to the 2018 Alltech Global Feed Survey. The growth seen in 2017 was strong at 2.57% over last year. The feed industry, valued at $ 430 billion, has seen a 13% …