Poor geometrical quality leads to material overuse. Description Deliverables. As an extrusion innovator, Maillefer can help you control sagging in the CCV lines better. That will be done by the off-set in the crosshead, twisting of the cable core, CV process parameters and EHT. In some cable constructions, low sag compounds are applied.

2022-7-19·Vulcanization is a relatively simple process of changing rubber’s natural structure, shaping the resulting material, and heat-curing it. Specific steps are: Rubber is submerged in a tank filled with sulfur and special additives which speeds up the curing process. Other additives may also be included with the rubber to enhance performance ...

China Vacuum Rubber Extruder - Select 2023 Vacuum Rubber Extruder products from verified China Vacuum Rubber Extruder manufacturers, suppliers on Made-in-China.com.

2023-1-19·REMA TIP TOP EXTRUDER GUNS (MADE IN EU) - feature a high quality drive, and adjustable heat controls. Models available for Light Truck, Truck and Earthmover applications. ... Rope Rubber; Vulcanizing Compounds; Retread Rubber Products - Specialty Chemicals; ... EXPEL 30 Filter & Auto Drain Set; Tire Service Cabinets and …

2015-8-3·You use an Autoclave or Vulcanizer (Vulcanizing autoclave) to convert natural rubber into a cured and chemically cross-linked rubber product. A vulcanized rubber is less sticky and gives you superior mechanical properties. Rubber Vulcanization (a term coined by Thomas Hancock) “process” was discovered accidentally by Charles …

2020-10-6·Formela, K. & Cysewska, M. Efficiency of thermomechanical reclaiming of ground tire rubber conducted in counter-rotating and co-rotating twin screw extruder. Polimery 59 , 231–238 (2014).

Full automatic rubber tile floor press with hydraulic pull push device 1 set (Min. Order) 1300X1500mm 6 Daylights Foam Rubber Sheets Vulcanizing Press/EVA Foaming Machine

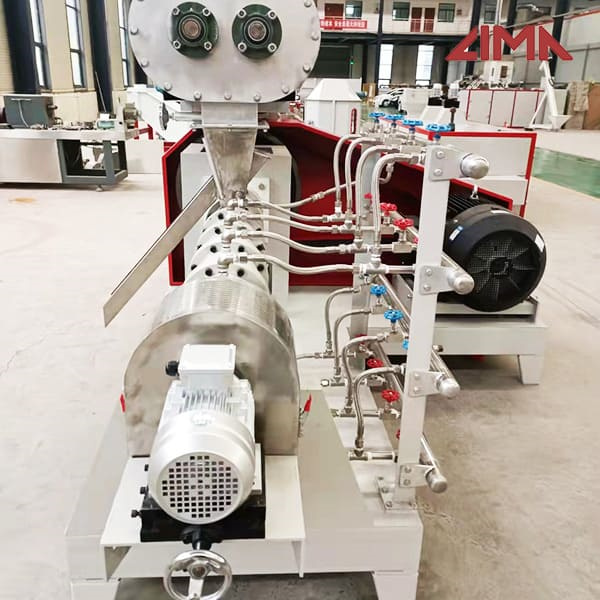

Rubber Calender. Knitting rubber hose extrusion line. NBR+PVC & EPDM foaming continuous production line. 3-composited rubber profiles microwave vulcanization line for auto. Common Hydraulic Vulcanizing Press Machine. Rubber strainer. Vacuum cold feeding rubber extruder. Pin-barrel cold feeding rubber extruder.

1. Rubber Cold Feed Extruder is used in production of band, strip and tubular shape of dense and foam rubber products which used in building, electrical, mechanical, water conservancy etc industry. 2. Production process: Raw materials - mixer - rubber mixing machine - extruder - vulcanizing box - cooling traction - packaging and storage. 3.

High Efficiency Tyre Shredder Machine; Rubber Tyre Crusher Cracker Mill; Automobile Brake Pads Making Machine; Solid Tyre Vulcanizing Press Machine; High Quality Waste Tire Debeader Machine Wear Resisting 30~50 Tires/H; Rubber Batch Off Cooler Floor Standing; Cold Feed Rubber Extrusion Machine For EPDM Rubber Strip Production Line

2023-2-14·OULI MACHINE Oil cylinder; The material of the oil cylinder is high quality QT500-7, ductile iron QT-500 is passivated after aging, or forging material is used, tensile strength ≥50kgf/mm The plunger is made of LG-P chilled alloy material, which has high surface hardness and is not easy to wear. The depth of the chilled layer is 8-15mm and …

2022-7-1·China Rubber Extrusion Microwave Continous Vulcanizing Line (XJW-90X20D), Find details about China Micrwoave Vulcanizing Line, Microwave Vulcanizing from Rubber Extrusion Microwave Continous Vulcanizing Line (XJW-90X20D) - Qingdao Biz International Trade Co., Ltd. ... Auto, Motorcycle Parts & Accessories; Bags, Cases & …

2020-11-2·What is rubber extrusion and what does the process involve? Rubber extrusion is the process of turning rubber materials into a specifically shaped product. To provide this shape, manufacturers use a rubber extruder machine. The rubber extruder has two main parts: a heated shearing screw conveyor and a die. The raw rubber material is …