2021-2-15·However, due to shortage of feed, there has been a gradual shift from traditional feed pattern to compound feed (CF). For livestock it is either in the form of mash, feed block or feed pellets ...

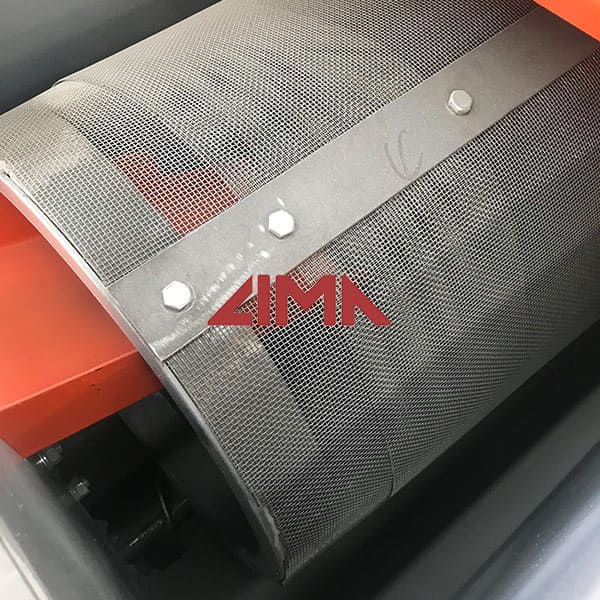

The animal feed manufacturing plant is a ring-type animal cattle feed production line, which has the characteristics of high-precision gears. The granulator is specially designed for stress-free and smooth transmission of the main shaft, long service life of the shaft, and low noise. it can be equipped with a non-stop refueling system.

2021-11-5·Step 1: Preparation Of Raw Materials. First, the cattle pellet machine receives the raw materials. The most used raw materials are soybean, corn, wheat, grass, etc. You should feed 1 kg pellet feed for the body maintenance of the cow. But, it will be changed to 1.25 kg/day in the case of buffalo.

2021-8-3·Grinder, mixer, pelleting machine, freezer, sifter, weight scale, packaging bags and more are some of the necessary feed processing equipment for starting a complete cattle feed production factory. Here you can see a 3-5 ton/h cattle feed manufacturing process flow chart. This process and layout was designed for one of our …

2023-1-19·Our small feed pellet line is can produce 2-8mm of feed pellets, the yield is 0.6-3t/h. This feed complete machine set is widely used in small and medium size of feed pellet production line, livestock farms and individuals who raise animals, etc. The feeds are suitable for pigs, cattle, sheep, rabbits, chickens, ducks, geese and other aquatic ...

2020-2-22·② The cost of making pellet feed is 8% ~ 9% higher than making powder feed; ④ The energy (electricity) consumption for manufacturing pellet feed is large; ⑤ The service life of the ring membrane of the granulator is 3000 tons to 7000 tons. In summary, the pellet feed produced by the feed pellet machine is better than the powder in terms ...

2014-5-4·Cattle feed pellets can be prepared from oil cakes, agro-residues such as peanut seedling, grass, maize straw, wheat straw, grain, wheat bran etc., flour mill by-products, cereals, molasses, and so on. ★ Raw and auxiliary materials are first charged into silos and tanks where they are made ready for further processing.

2022-8-24·The feed structure must support stomach health and should be appropriate depending on the cattle stage of development. The most common ingredients you need to make your own cattle feed include protein cakes/meals, vitamins, minerals, grains, sunnies, brans, and agro-industrial by-products. ... Used to produce cattle feed pellets; Feed pellet ...

2021-2-15·However, due to shortage of feed, there has been a gradual shift from traditional feed pattern to compound feed (CF). For livestock it is either in the form of mash, feed block or feed pellets ...

2022-5-12·1.Determine the scale of cattle feed mill. 2.Determine the feed process and recommend cattle feed machine. 3.Control mode selection. 4.cattle feed manufacturing plant structure selection. 5.Planning the general drawing of cattle feed mill plant site. 6.We devote ourselves to undertaking all cattle feed production line 1-100 T/H.

The animal feed manufacturing plant is a ring-type animal cattle feed production line, which has the characteristics of high-precision gears. The granulator is specially designed for stress-free and smooth transmission of the main shaft, long service life of the shaft, and low noise. it can be equipped with a non-stop refueling system.

2015-7-13·Conditioning the feed at a temperature of 80° C is sufficient to produce good quality pellets. The minimum time that feed should stay in the conditioning tube to produce durable pellets is 30 seconds. Long time conditioners, in which the feed can stay in the conditioner for about 3-4 minutes, can be used to improve pellet stickiness. Thicker ...

Feed pellet production line is a complete set of machines that are specifically used to make feed pellets. The key machines like hammer mill, feed mixer and feed pellet machine are patented product through 10 years research and development combined with advanced technology by Shandong Double Crane Machinery Manufacture Co.,Ltd.

1 ·The main types of cattle feed are cattle cubes, pelleted cattle feed, and textured cattle feed. Cattle Cubes. Cattle cubes help your herd maintain both their weight and condition because they are formulated to supplement fair and low-quality forage. Cattle cubes provide the protein, minerals, and vitamins a cow’s forage sometimes lacks ...

2021-3-5·Cattle feed pellets. Among the full-price compound feeds, energy feeds account for about 55-75% of the total components, followed by protein feeds, accounting for 20-30% of the total feeds, and again are mineral nutrients, except for eggs. Outside of poultry, generally ≤5%, other such as amino acids, vitamins and non-nutritive additives ...

2014-5-4·Cattle feed pellets can be prepared from oil cakes, agro-residues such as peanut seedling, grass, maize straw, wheat straw, grain, wheat bran etc., flour mill by-products, cereals, molasses, and so on. ★ Raw and auxiliary materials are first charged into silos and tanks where they are made ready for further processing.