Extruded Floating Fish Feed Food Manufacturing Machine 200-300kg/H ... Feed Pellet Machine, Snack Food Machine, Briquette Processing Machine, Grinder Crusher Machine, Vegetable Processing Machine, Dryer Machine, Construction Machine ... Floating Fish Food Machine Fish Food Machine Floating Fish Feed Pellet Machine Animal Feed Pellet Mill …

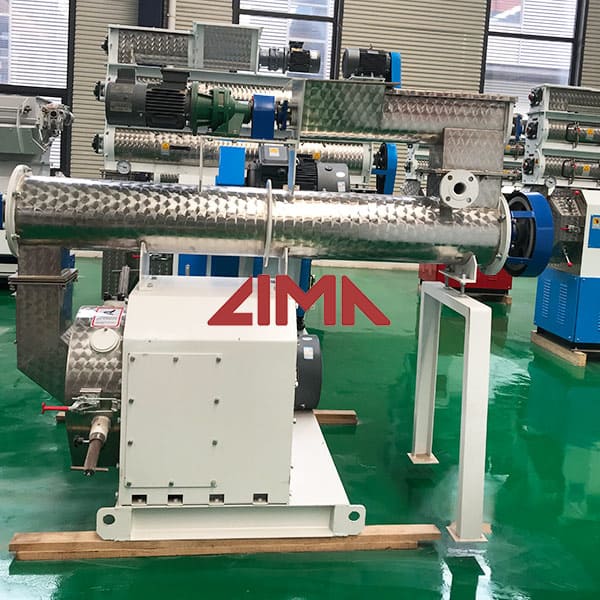

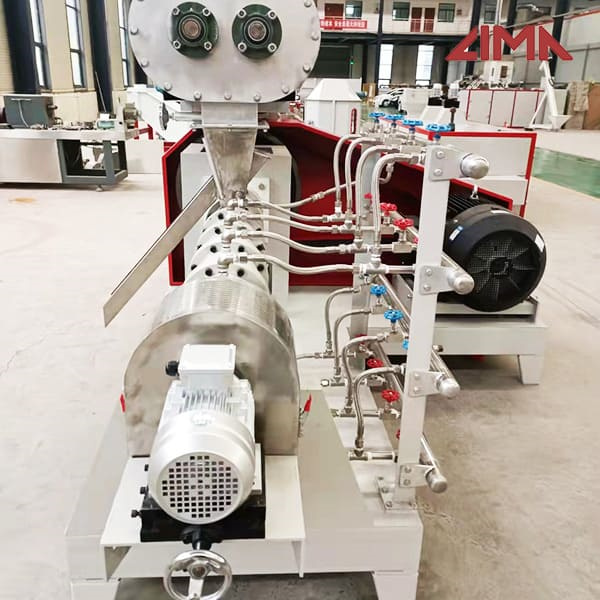

It is more suitable for extrusion processing of materials with high moisture and high oil content. Aquatic feeds, especially marine fish feeds, generally have higher fat content, so twin-screw fish feed extruders are more suitable. Capacity: 1.5-12 T/H. Price of twin-screw extruder machine: 70,000-200,000USD USD.

2022-12-7·With the further development of fish farming industry, compound fish food pellets have obtained more and more wide applications in virtue of unique advantages including high nutrient, good palatability, strong digestibility and so on. There are 3 types of sinking fish feeds machine available for processing sinking fish feed pellets: sinking pellet …

2022-11-2·Basically, there are two type of machines for fish food production: Ring die pellet mill and twin screw extruder: Twin screw extruder makes floating fish feed, it deliver the mixed fish food powder smoothly by double screw inside, during this process, the fish food can reach more than 100 °C in the screw. When the fish food is extruded through ...

Sinking Fish Feed Making Machine. Sunwit is a professional fish feed machine manufacturer. We help small, medium and large-scale fish pellet production clients set-up a fish feed plant that is designed to meet customers‘ specific demands at different capacities. Sinking fish feed machine (500kg-4t/h) The fish feed extruder is a ...

2020-7-22·5.1 Fish feed extruder for making milkfish/tilapia feed. Milkfish and tilapia prefer to eat floating fish feed pellets. Thus for milkfish or tilapia feed pellet producers or milkfish/tilapia farmers, fish feed extruder is the best choice. Fish feed extruder is mainly used to make floating fish feed pellets.

Floating Fish Feed Extruder Machine; Floating Fish Feed Mill; Shrimp Feed Mill; ... 12-14T/H Fish Feed Manufacturing Plant; 16-20T/H Fish Food Factory; Cases Menu Toggle. ... (mainly straw, flue-cured tobacco rods, etc.), which are extruded into rod-shaped biomass pellet fuels through the pressure of a biomass pelletizer. The site of this ...

You can buy factory price crab feed from a great list of reliable China crab feed manufacturers, suppliers, traders or plants verified by a third-party inspector. Source with confidence. -page3

Extruded Floating Fish Feed Food Manufacturing Machine 200-300kg/H ... Feed Pellet Machine, Snack Food Machine, Briquette Processing Machine, Grinder Crusher Machine, Vegetable Processing Machine, Dryer Machine, Construction Machine ... Floating Fish Food Machine Fish Food Machine Floating Fish Feed Pellet Machine Animal Feed Pellet Mill …

It is more suitable for extrusion processing of materials with high moisture and high oil content. Aquatic feeds, especially marine fish feeds, generally have higher fat content, so twin-screw fish feed extruders are more suitable. Capacity: 1.5-12 T/H. Price of twin-screw extruder machine: 70,000-200,000USD USD.

2022-11-15·Feed produced with these processes is denser, has lower moisture content and allows better preservation. One of the main differences between pelleted and extruded feed is that, whereas pellets sink, the buoyancy of the extruded feed can be controlled during the manufacturing process. However, extrusion has other advantages …

High efficiency, low power consumption. 4. Screw sleeve of this small fish food extruder adopts enchase alloy steel strip structure, which guarantees long service life. 5. Different moulds can be chosen to make pellets with different diameters and shapes. 6. Feed pellets dia. Is 0.9-15mm. 1.0mm floating fish feed.

2022-3-8·their byproducts. They have been classified into Dry type fish feed machine and Wet type fish feed machine. The aim of designing and developing the fish food pellet machine is to affordable to local fish farmers and maintain the nutritional value. Machine produces different shapes and size of food by changing the pellets.

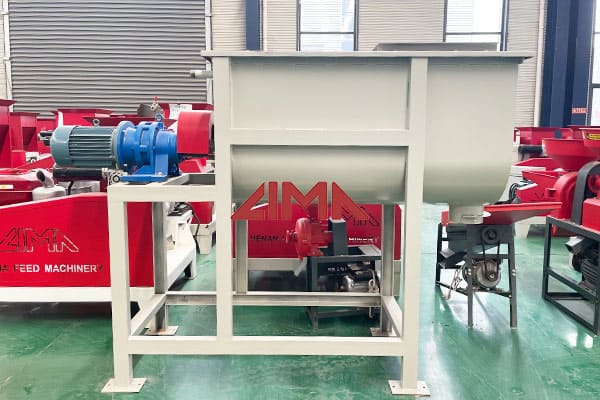

2021-11-26·For large factories however, the wet type feed extruder that has a conditioner will be able to produce in large quantity, a high quality fish feed pellet. Get Fish Feed Extruder Price! 4. Drying Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryer should be equipped in the production …

Pet food production line is designed to produce pet food pellets, also animal feed for every kind of animals, like cats, dogs, foxes, mink, rabbits, fish, shrimps, poultry, livestock, birds and other pets.. By adjusting the ratio of raw materials, processing temperature, moisture, extrusion pressure and other production processes, it can make the product have …

2022-12-6·When the fingerlings are stocked, when the water temperature is low, the growth is slow, and the size is small, the particle diameter of the feed should be controlled at about 2mm; when the ...

Floating Fish Feed Extruder Machine; Floating Fish Feed Mill; Shrimp Feed Mill; ... 12-14T/H Fish Feed Manufacturing Plant; 16-20T/H Fish Food Factory; Cases Menu Toggle. ... (mainly straw, flue-cured tobacco rods, etc.), which are extruded into rod-shaped biomass pellet fuels through the pressure of a biomass pelletizer. The site of this ...

2020-7-15·The differences are the following: 1.A pellet mill shapes the pellets by compression through long land dies thus the pellet is dense. In most cases, a pellet binder is need in the formula to facilitate the cohesion of the pellet. 2.An extruder will expand the pellet through substantial gelatinization of the starch, expansion and increased ...