2023-2-16·Published Feb 16, 2023. + Follow. The vibrating feeder is also called the vibrating feeder. The vibrating feeder is used in the production to feed the massive and granular materials from the ...

2022-7-13·Vibrating screen selection is based on several factors, including maximum tons per hour, gradation of the feed material, type and weight of material, desired size of separation, any surface moisture on material and any special operation requirements, including physical characteristics of the feed or product requirements. 3.

2020-9-9·The design of the feed chute is key in improving the efficiency of classification, increasing the service life of liners and screening media, and ensuring the structural integrity of the vibrating screen. The feed material distribution has to be along the entire width of the equipment to take full advantage of the entire screening area of the ...

2023-1-31·Global Biometric Sensor Market size is expected to reach $3.31 billion by 2030 from $1.16 billion in 2020, growing at a CAGR of 11.8% from 2021 to 2030.

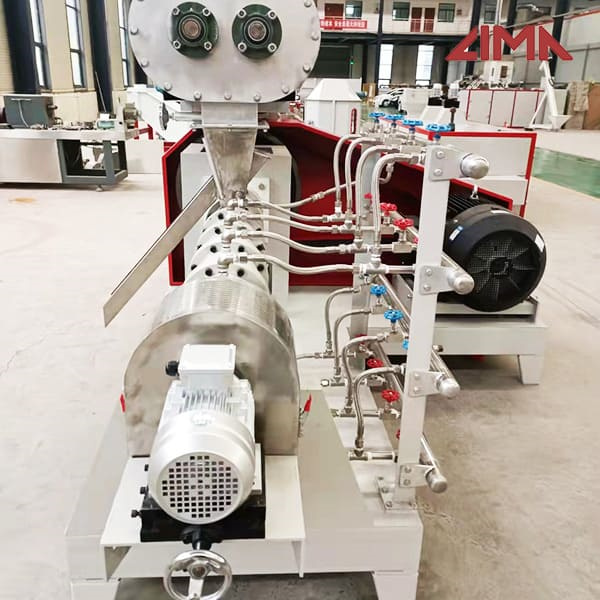

Hi-Efficient Lowest Price Feed Process Machine Sifter Screen Machine 1. Domestic famous brand motor and bearing; ... Industrial flour sifter maize starch square plansifter vibrating screen machine is driven by a motor which installed underside of the main frame and counter-balanced by a counterweight. There are single section type, double ...

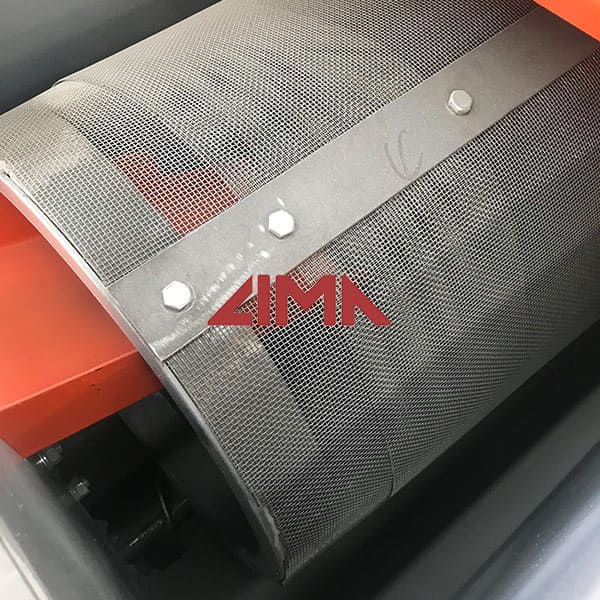

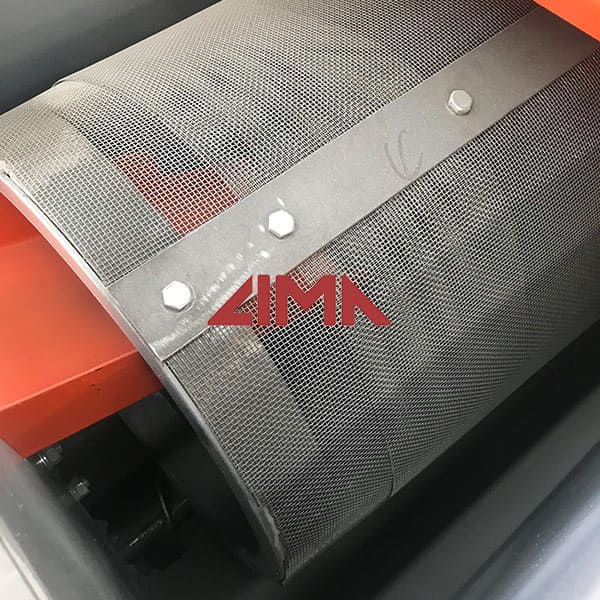

Rotary Screen which is shaped like a large tube, where the tube has holes. The rotary screen consists of inputs and outputs, where the feed goes into the input. Inside the input, the feed is rotated by the screen at a specified speed. The unwanted feed will exit by

2022-2-15·Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

2023-2-16·Published Feb 16, 2023. + Follow. The vibrating feeder is also called the vibrating feeder. The vibrating feeder is used in the production to feed the massive and granular materials from the ...

Boons & Benefits: 1. Lower Operational Costs. Known for their robust framework, the vibrating screen’s functional principle is straightforward and the machine is streamlined. They are purchased at considerably lower rates as compared to other screeners. In addition to this, the vibrating screens are operational at much lower energy and ...

The utility model relates to a feed processing machinery field discloses kind fodder shale shaker device, which comprises a frame, vibrating device, shale shaker box and hopper, install vibrating screen and lower vibrating screen in the cavity of shale shaker box, separate into the upper cavity with the cavity of shale shaker box from last to lower, middle level …

1 ·Vibratory screen troubleshooting. 1. The material flow on the vibrating screen is abnormal. First, the rigidity of the screen box is insufficient, there is a critical frequency, the connecting bolt has been loosened, and even to the extent of full vibration, that is, tightening. Second, the horizontal level of the screen box is not accurately ...

2022-5-25·The method of increasing the output of vibrating screen. 1. Improve the opening rate of the screen mesh. Because the ore is relatively large in mesh, a metal woven mesh or punching plate with a large aperture is generally used. If you want to increase the output, you can also replace the screen mesh with a larger aperture than the previous …

Hi-Efficient Lowest Price Feed Process Machine Sifter Screen Machine 1. Domestic famous brand motor and bearing; ... Industrial flour sifter maize starch square plansifter vibrating screen machine is driven by a motor which installed underside of the main frame and counter-balanced by a counterweight. There are single section type, double ...

Rotary Screen which is shaped like a large tube, where the tube has holes. The rotary screen consists of inputs and outputs, where the feed goes into the input. Inside the input, the feed is rotated by the screen at a specified speed. The unwanted feed will exit by