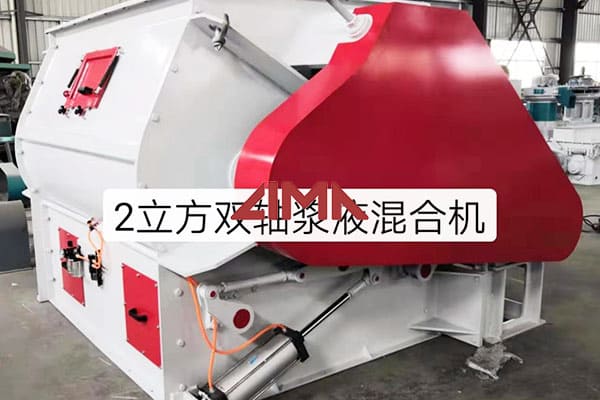

The twin-shaft paddle mixer is suitable for mixing of compound feed and feed ingredients. The mixer is supplied with a double gearbox drive and is in heavy-duty industrial execution. Quick filling and emptying, and full emptying through "bomb doors" are some of the advantages. It is possible to add up to 3 different liquids during the mixing ...

2015-6-9·New paddle mixer. In a quest to ease production, increase cost efficiency and high-quality results, the company ANDRITZ Feed & Biofuel Technologies, based in Denmark, has developed a new type of mixer, the OptiMix paddle mixer, which has a shorter mixing time. The new patentable design features are unique to the market.

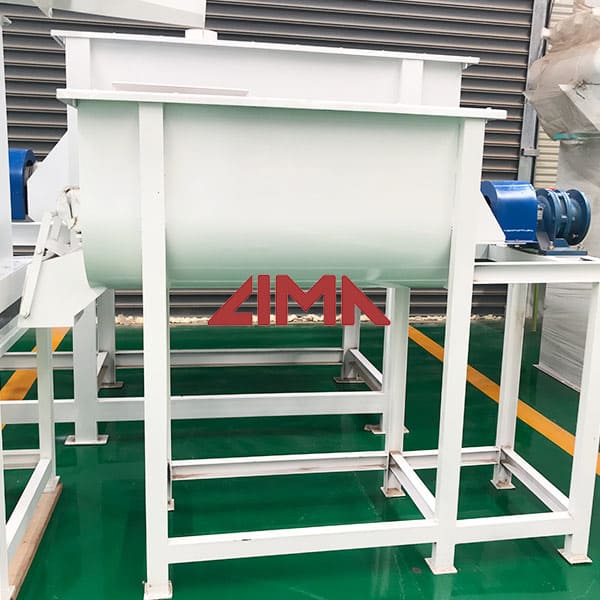

1 ·The products cover feed production line: Raw material receiving, crushing, mixing, pelleting, extrusion, drying, coating, etc., as well as automated quantitative packaging of various industries. The company is located in Nanchang, Jiangxi, with a registered capital of 10 million yuan, covers an area of 20, 000 square meters, and has two large ...

2022-5-29·Single Roller Double Paddle Mixer ; Small Vertical Feed Mixer ... Construction scale: Build 3 animal feed production lines, ... Three-layer paddle high-efficiency mixer: 1000~2000kg/batch F series hardened gear reducer: 3: Self-cleaning scraper: TGSU 25 type, 3.0kw×1 unit ...

Purpose of Use. The range of FEEDTECH mixers, both single & twin shaft, have been designed to mix a wide range of raw materials, additives and liquids into a homogeneous animal feed mixture, within a short mixing time. Double Shaft Paddle Mixer-DPMA Series are used for mixing several powdery substances into a homogeneous mixture.

Pugmill mixers are frequently used as an industrial mixing solution. In a mixing setup, the mixer can be used as a stand-alone unit, or as part of a larger system. Pugmill mixers provide thorough mixing for both end products and raw feedstock materials. Materials that are commonly mixed in a pugmill mixer include: FGD Scrubber Sludge; Municipal ...

2023-2-6·1. The double shaft paddle feed mixer has a short mixing cycle and high mixing uniformity, which reduces the mixing time and greatly improves the production efficiency. 2. The variable loading range is large, suitable for different specific gravity, particle size and other materials in various industries: mixing of materials. 3.

It provides a mixture of raw materials that are grinded at 1/100,000 mixing sensitivity. Flexible mixing. Paddle mixers have body sizes ranging from 500 liters to 16.000 liters. The desired mixing ratios are achieved at the filling levels between 10% and 100% of the mixer. Thanks to the nozzles on the mixer, the process of adding liquid into ...

1 ·The products cover feed production line: Raw material receiving, crushing, mixing, pelleting, extrusion, drying, coating, etc., as well as automated quantitative packaging of various industries. The company is located in Nanchang, Jiangxi, with a registered capital of 10 million yuan, covers an area of 20, 000 square meters, and has two large ...

2015-6-9·New paddle mixer. In a quest to ease production, increase cost efficiency and high-quality results, the company ANDRITZ Feed & Biofuel Technologies, based in Denmark, has developed a new type of mixer, the OptiMix paddle mixer, which has a shorter mixing time. The new patentable design features are unique to the market.

2023-2-6·1. The double shaft paddle feed mixer has a short mixing cycle and high mixing uniformity, which reduces the mixing time and greatly improves the production efficiency. 2. The variable loading range is large, suitable for different specific gravity, particle size and other materials in various industries: mixing of materials. 3.

Pugmill mixers are frequently used as an industrial mixing solution. In a mixing setup, the mixer can be used as a stand-alone unit, or as part of a larger system. Pugmill mixers provide thorough mixing for both end products and raw feedstock materials. Materials that are commonly mixed in a pugmill mixer include: FGD Scrubber Sludge; Municipal ...

2016-1-1·Abstract. Justification of the use of mixers in the processing of mixtures’ feed is given in the article. Some designs of mixers are considered, research of some authors are noted. Existing shortcomings of the mixing process and designs of mixers are revealed. The sound design of a double-shaft mixer with a horizontal shaft and rectangular ...

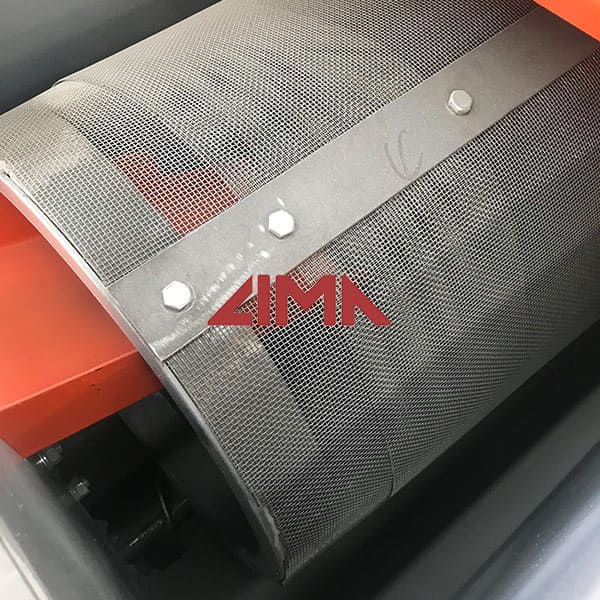

paddle mixer WBHP - WBHT. plowshare batch for liquids. Engine power: 22 kW - 200 kW. Capacity: 165 l - 20,000 l. Empty weight: 650 kg - 8,000 kg. ... outlet opening over the entire length of the mixing drum ensures almost residue-free discharge of the product in the shortest possible time. WBHP / WBHT Bomb-Bay Discharge Batch Mixers are the ...

It provides a mixture of raw materials that are grinded at 1/100,000 mixing sensitivity. Flexible mixing. Paddle mixers have body sizes ranging from 500 liters to 16.000 liters. The desired mixing ratios are achieved at the filling levels between 10% and 100% of the mixer. Thanks to the nozzles on the mixer, the process of adding liquid into ...