1 ·The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

China Fish Food Twin Screw Extruder - Select 2023 Fish Food Twin Screw Extruder products from verified China Fish Food Twin Screw Extruder manufacturers, suppliers on Made-in-China.com.

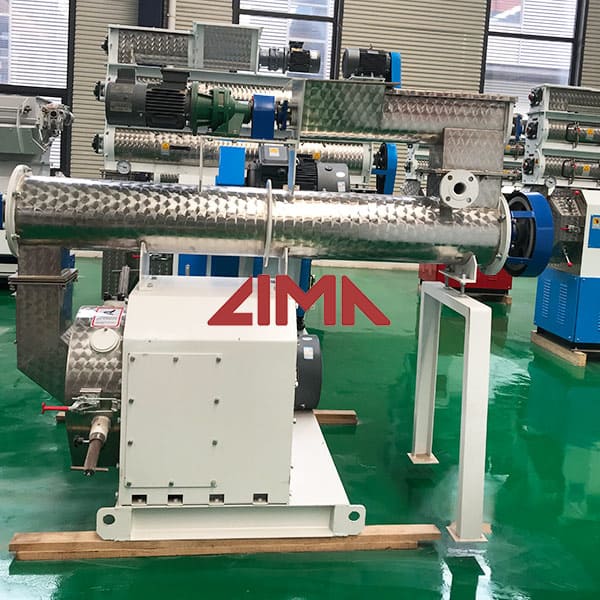

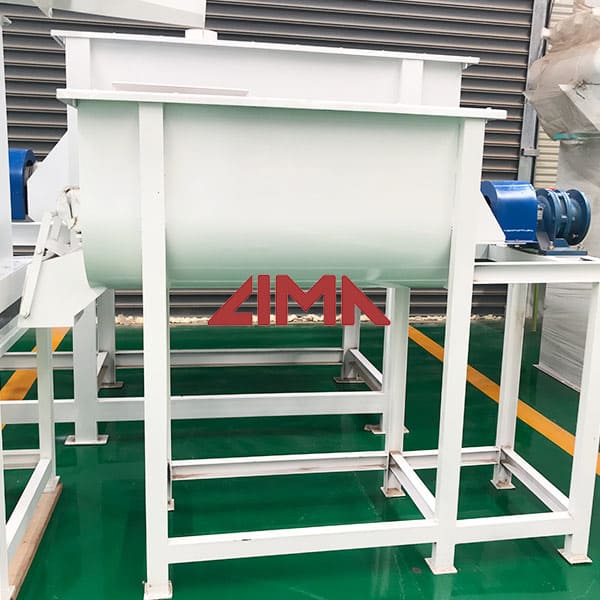

Our product advantages: 1. The main motor adopts frequency conversion control, which is energy-saving and easy to operate. 2. Adopt frequency conversion speed control feeder, and feed evenly. 3. The maturity of materials is sufficient, and the gelatinization degree of materials is over 98%. 4.

2022-9-5·The fish food pellet machine simply compresses the material into pellets by extrusion, which is also called a fish pellet making machine. The maturity of the material is very low. The fish feed pellet extruder uses the screw to cut, compress, and knead the material to fully mature, and then the screw compression ratio and length to diameter …

Waleed Yacu, in Extrusion Cooking, 2020. 1 Introduction. Extruders are used for making a wide range of food products. Their design and specifications should be tailored for the intended application, from simple forming applications such as pasta products, to very short cooking extruders for corn curls, to more complex and long extruders involving multiple …

23. Austria Sells Industrial Dog Food Machine 100kg/h. 24. 50Kg/H Small Dog Food Extrusion Machine For Sale In Botswana. 25. Sudan 50kg/h Small Dog Food Production Line. 26. Algerian Dog Food 300kg/h Production Line. single screw cooking forming extruder manufacturer of semi-finished pellets chips and snacks making.

100-5000kg Stainless Steel Fish Food Pellet Production Line Features of fish food pellet production line: 1. The main motor is frequency conversion control, which is energy saving and easy to operate. 2. This machine is frequency-converting speed-adjusting.....

![<h3>[PDF] DESIGN AND CONSTRUCTION OF A FISH FEED …</h3>](/wp-content/themes/lima/load/50/floating fish feed pellet making machine63.jpg)

2016-8-1·Design and fabricated of a fish feed extruder with improved qualities and affordable cost, the design was carried out using engineering principles with due consideration to cost, ease of operation ...

2014-12-17·Abstract: The performance of a developed floating fish feed extruder was evaluated. The effect of some parameters such as; screw speeds (100 rpm, 150 rpm, and 200 rpm), moisture content of ration (20 %, 25 %, 30 % and 35 %), and die diameters (3 mm, 5 mm, 9 mm) on specific mechanical energy requirements, expansion

100-3000kg/Hr Industrial Automatic Wet Dry Animal Pet Dog Cat Food Extruder Fish Feed Making Machine Production Line Processing Plant FOB Price: US $7,000-17,000 / Set Min. Order: 1 Set

Our product advantages: 1. The main motor adopts frequency conversion control, which is energy-saving and easy to operate. 2. Adopt frequency conversion speed control feeder, and feed evenly. 3. The maturity of materials is sufficient, and the gelatinization degree of materials is over 98%. 4.

2022-9-5·The fish food pellet machine simply compresses the material into pellets by extrusion, which is also called a fish pellet making machine. The maturity of the material is very low. The fish feed pellet extruder uses the screw to cut, compress, and knead the material to fully mature, and then the screw compression ratio and length to diameter …

2015-9-10·The final temperature and pressure depend on whether low- or high-viscosity PET is being produced. For high-viscosity PET, the pressure in the final (or second) end finisher is less than 2 mm Hg. With high-viscosity PET, more process vessels are used than low-viscosity PET to achieve the higher temperatures and lower pressures needed.

2016-12-8·To do sinking pellets you need: 1. To have a technological opening in the penultimate section of the extruder. 2. Modification of the screws must be assembled for sinking feeds. 3. The area of the holes in the matrix must meet the requirements of sinking feed. 4. Composition of the recipe table.

At Radius Systems, traditional DC motors powering extrusion lines are gradually being replaced with AC motors in an effort to improve energy use, lower maintenance and reduce noise. Radius Systems, part of the Polyplastic Group of companies, designs, develops and manufactures plastic piping systems for the utilities, telecoms and construction ...

100-5000kg Stainless Steel Fish Food Pellet Production Line Features of fish food pellet production line: 1. The main motor is frequency conversion control, which is energy saving and easy to operate. 2. This machine is frequency-converting speed-adjusting.....