2022-12-31·Leading technology of high-efficient screw with L/D ratio of 40. Single Screw Extruder energy saving heaters from Blesson machinery, China extruder. The screw and barrel are made of high-strength alloy steel (38CrMoALA) with nitriding treatment, which is corrosion-resistant and long-lasting. Bimetal barrel optional for impure material to …

2013-5-2·Thermal homogeneity was assessed using thermocouple grid and infra-red techniques. The thermocouple grid sensors used in this work have been described in detail previously including calibration techniques and quantification of shear heating and conduction errors. These devices consist of a two dimensional array of interconnected …

2020-4-11·As was mentioned by Severs, [] the correct performance of the plastication process has a positive effect on the structural, physical, and mechanical development of final polymeric products. In the plasticating region, some of the heat energy is supplied by external heaters. However, the mechanical energy of the rotating screw is the major …

2020-1-10·screw extruders. With the quad screw extruder, drive torque increased with increasing feed rate10. This work compared the energy consumption for ultra-high speed twin and quad screw extruders. Energy consumption was measured directly from the extruders and correlated with drive torque, melt temperature, and viscosity obtained from …

Plastic extruders manufacturer . Bausano is an expert plastic extrusion manufacturer, producing a fully customizable range of plastic extruders for a variety of sizes, applications and materials.. From a lab scale extruder up to industrial production capacity with Single and Twin-screw extruders, we provide every kind of bespoke extruders tailored to your needs.

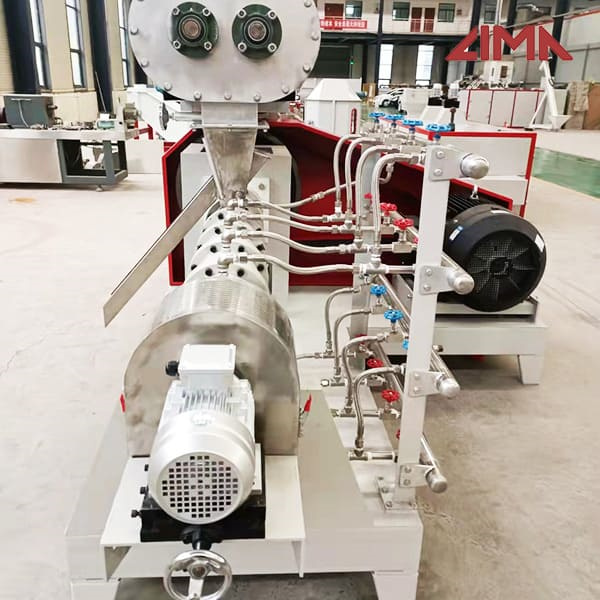

Twin screw extruders are available for research and development purposes to process as little as a 50-gram batch, and for full-scale production at rates of 50,000+ kgs/hr. The attributes inherent with a twin screw extruder makes it the preferred manufacturing methodology for the continuous mixing of commodity and high-tech precision products.

2021-9-29·The attributes inherent in continuous compounding with twin-screw extruders make these devices unmatched for both commodity and high-tech precision products. Twin screw extruders utilize unique screw-to-screw flows that are effective, rapid, efficient, and capable of achieving both dispersive and distributive mixing.

Melt Conveying in Single-Screw Extruders: Modeling and Simulation. Polymers 2022, 14 ... Investigations of the Elongational Deformation Induced by Pins in Pin-Barrel Cold-Feed Extruders. Advances in Polymer Technology 2022, 2022 ... Effect of the dispersed phase fraction on particle size in blends with high viscosity ratio. Polymer ...

Polymer extrusion is regarded as an energy intensive production process, the real-time monitoring of both thermal energy and motor drive energy consumption becomes necessary for the development of energy efficient management system. The use of power meter is a simple and easy way to achieve this, however the cost sometimes can be high.

2020-1-10·screw extruders. With the quad screw extruder, drive torque increased with increasing feed rate10. This work compared the energy consumption for ultra-high speed twin and quad screw extruders. Energy consumption was measured directly from the extruders and correlated with drive torque, melt temperature, and viscosity obtained from …

2022-12-1·A single-precision mantissa multiplication can be implemented using only one variable-precision block configured in the high-precision mode. The designer can choose to use the internal coefficient storage or bypass it. A single variable-precision DSP block can implement different multiplication operations for each precision mode, as …

A single-screw extruder is a press which pushes material through its barrel under conditions of high pressure and temperature. It can produce objects of different length with a cross-section corresponding to the outlet opening. Applications. The extrusion process melts the raw material and then hardens it once shaped.

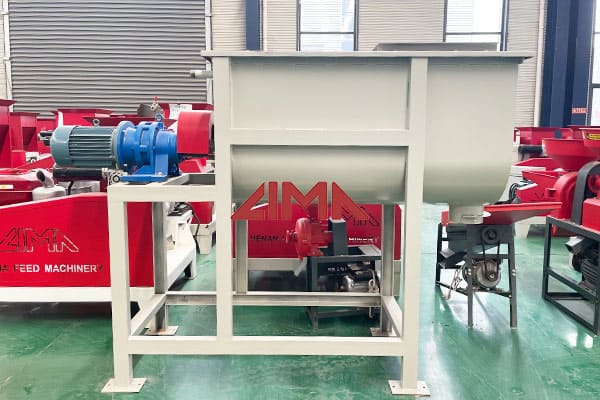

As Pet Food Extruder Machine manufacturers had designed High Quality Twin Screw pet Extruders used for pet food and fish feed production, developed and tested. The major components of the machine included the feeder hopper, the conditioning chamber (can be choose), the barrel that was a screw member housing and the screw with the die and die …

Twin screw extruders are available for research and development purposes to process as little as a 50-gram batch, and for full-scale production at rates of 50,000+ kgs/hr. The attributes inherent with a twin screw extruder makes it the preferred manufacturing methodology for the continuous mixing of commodity and high-tech precision products.

The Hot Feed Extruder is designed to take the material from the FCM™, Farrel Continuous Mixer, and features an oversized hopper opening that ensures efficient feeding. The continuous feed of material permits orientation of these extruders either parallel or at right angles to the axis of the FCM™ rotors. Standard Features Include:

2021-9-29·The attributes inherent in continuous compounding with twin-screw extruders make these devices unmatched for both commodity and high-tech precision products. Twin screw extruders utilize unique screw-to-screw flows that are effective, rapid, efficient, and capable of achieving both dispersive and distributive mixing.