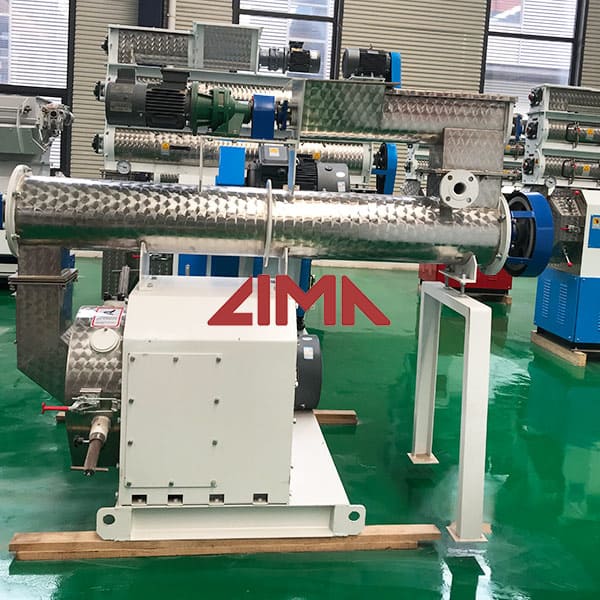

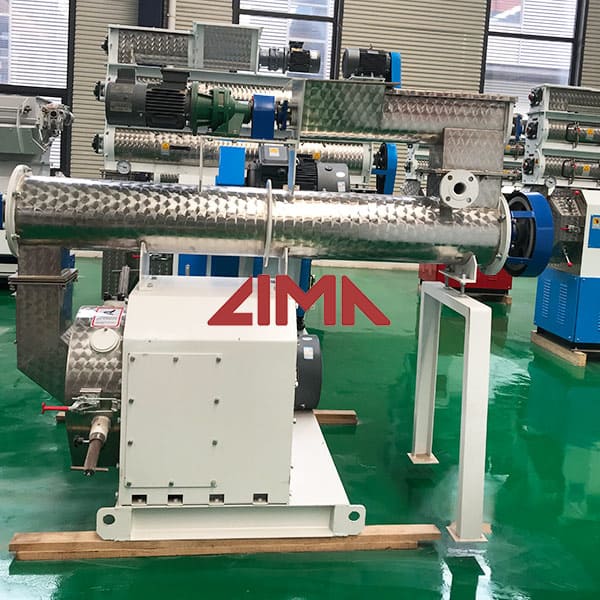

2023-2-15·The multifunctional single-screw extruder offers a modular design to meet a wide range of process requirements for your pet food and aqua feed production. Capacity, screw speed, torque and pressure options provide excellent versatility. Watch the video.

The ANDRITZ single screw extruders provide the latest technology for the production of pet food. Extruder – type EX1250. High capacity extrusion: 10-20 tph; High degree of processing flexibility; User-friendly design for operation and maintenance; Minimum downtime; Extruder – type EX1021. High capacity: 2-12 tph; Low-cost maintenance and ...

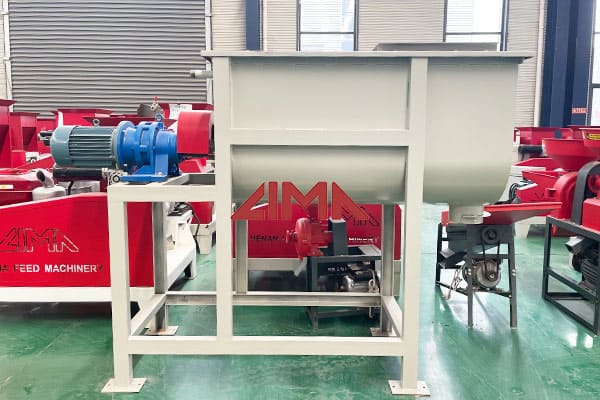

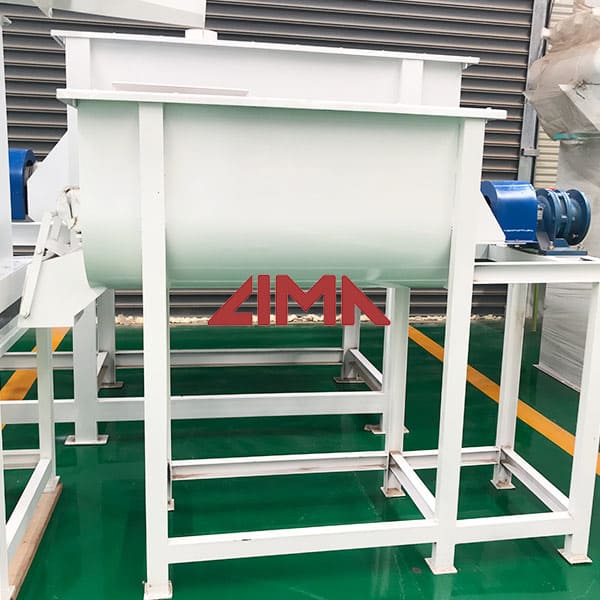

2. Pet Food Processing Line adopts corn flour, bone meal, fish meal as raw materials. 3. Different shapes can be made by adjusting the dies from extruder. 4. Output can be 1ton---3.5ton/h. 5. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries. 6.

welding extruder HSK-IE150. single-screw. Output: 5 kg/h - 15 kg/h. Screw diameter: 3 mm - 12 mm. Industrie Extruder HSK-IE150 for working with von polyolefine Granules or rods output app. 5 kg/h – 15kg/h Product Description drive with 3 KW power Type R40 F DT80N2 speed 2700 / 241 / 3300 ...

A single-screw extruder is a press which pushes material through its barrel under conditions of high pressure and temperature. It can produce objects of different length with a cross-section corresponding to the outlet opening. Applications. The extrusion process melts the raw material and then hardens it once shaped.

23. Austria Sells Industrial Dog Food Machine 100kg/h. 24. 50Kg/H Small Dog Food Extrusion Machine For Sale In Botswana. 25. Sudan 50kg/h Small Dog Food Production Line. 26. Algerian Dog Food 300kg/h Production Line. single screw cooking forming extruder manufacturer of semi-finished pellets chips and snacks making.

As a pioneer in the development of the closely intermeshing, co-rotating twin screw extruder, we possess a unique know-how and an extraordinary wealth of experience in this field. Coperion has continuously set new standards in machine and system design for processing technology since the 1950s. More than 15,000 installed compounding systems ...

2023-2-13·Millholland Conrad, Inc. Westfield, IN Distributor* $10 - 24.9 Mil 1960 1-9. Distributor of single screw extruders for plastic and rubber industries. Available in 3/4 to 9 in. dia. Profile, tubing, wire, cable, narrow web, laboratory and silicone extrusion machinery are available. Co-extrusion systems are also offered.

2022-11-7·In general, extrusion equipment used currently to process foodstuff falls into two major categories: twin-screw extruders and single screw extruders. Here is a detailed explanation of each type of equipment: Single screw extruder. The single screw extruder is simple. It is uses a rotating belt way and has a constant/fixed speed.

Melt-fed single-screw extruders. Perfect mixing, optimum degassing and reliable cooling combined with high throughput rates. KraussMaffei Berstorff single-screw extruders stand out for simple and robust machine construction, low need for maintenance, highest torques, and flexible configuration of the processing section.

Coperion’s twin screw extruder ZSK Mv PLUS provides ideal conditions for the extrusion of many types of food and pet food products. The process section of the ZSK twin screw extruder consists of several barrels in which the co-rotating screws operate. The closely intermeshing screws with their tight selfwiping profile eliminate stagnant zones ...

2016-7-4·It was in 1946 that single-screw extruders were used commercially for the extrusion cooking and expansion of corn snacks [5]. In the seventies, the use of twin-screw extruders became predominant. This trend has been continuing up to date. The first reported work on simulation and modeling of twin-screw extruder was done by Yacu in 1984 [12].

2020-2-1·Extrusion technology is applied in food processing industry for the development of variety of snacks, pasta, breakfast cereals, pet foods, supplementary foods and other textured foods. It is an ...

2017-1-11·Extruders with more than two screws have been used in the plastics industry but not in food processing. 3.1. Single-Screw Extruders Single-screw extruders contain a single rotating screw in a metal barrel, and come in varying patterns. The main design features are shown in Figure 5. The most commonly used single-screws have a …

2019-7-31·drastically changed. For example, in case of single-screw extruders, the output of 65mm screw diameter, was only 30 kg/hr. in 1950's (at present, more than 500 kg/hr.) and the cable coating speed was 66m/min (now, more than 2000 m/min) (Seikei-Kakou, 2005). Recently, the capacity of processing machines was ... For example a large …

2022-11-7·In general, extrusion equipment used currently to process foodstuff falls into two major categories: twin-screw extruders and single screw extruders. Here is a detailed explanation of each type of equipment: Single screw extruder. The single screw extruder is simple. It is uses a rotating belt way and has a constant/fixed speed.

High Moisture Meat Analogs (HMMA) are plant-based products designed to mimic whole muscle meat. They can be created to: Exhibit similar characteristics for moisture, protein and fat contents. Feature a densely layered, somewhat fibrous structure. Contain between 50% and 80% moisture after extrusion, corresponding to their whole meat counterparts.

2023-2-13·Millholland Conrad, Inc. Westfield, IN Distributor* $10 - 24.9 Mil 1960 1-9. Distributor of single screw extruders for plastic and rubber industries. Available in 3/4 to 9 in. dia. Profile, tubing, wire, cable, narrow web, laboratory and silicone extrusion machinery are available. Co-extrusion systems are also offered.