Roskamp Champion steam chambers are designed and sized to specifically fit your unique steam-flaking application. Our one-of-a-kind steam inlet design ensures uniform flow and low-velocity, high-volume steam addition. The vertical, inversely tapered design allows for grain expansion, and the smooth, obstruction-free interior allows for uniform ...

2023-2-18·You will learn how to make a corn mill efficient - basic milling processes, machine design and plant operation. Everything from intake to the finished product. But you also get practical experience. You will spend time in front of key machines in our training center hall to learn cleaning, conditioning and milling techniques.

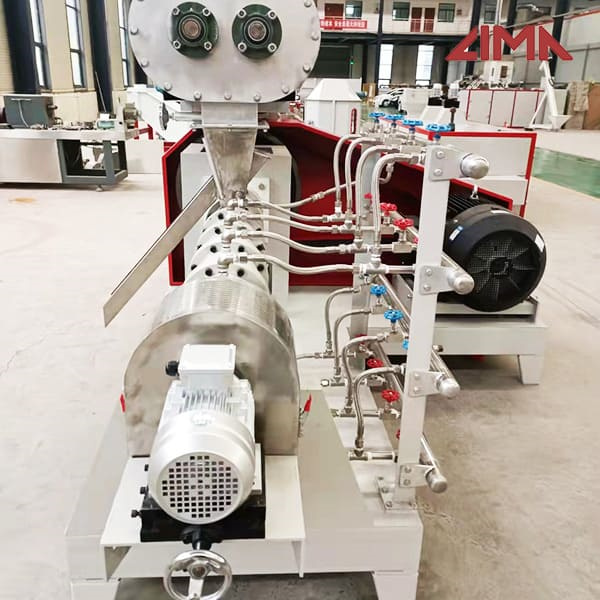

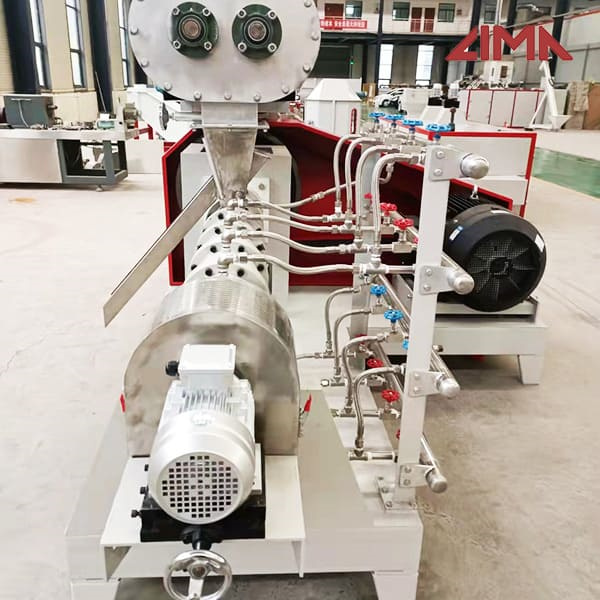

The corn flakes production line takes corn flour as the main raw material for production. Through raw materials mixing, twin screw extruder, high temperature extrusion, flaking, and pre-drying with a multi-layer mesh belt dryer, sugars spraying (such as maltose can be added through a sugar spraying and mixing system), and high temperature baking, …

2021-3-6·February 5, 2019. Depending on the moisture of the corn you would typically need to add 3 to 6% moisture content in the form of steam to achieve 18 to 20% in the steam chamber. If you are flaking 6 MTH of corn and the corn arrives at 14% moisture you would need to add 5 to 6% in the form of steam or 660 to 792 #/hour of steam to reach …

2019-3-5·January 23, 2019. Mohamad; The moisture content entering the flaking mill should be close to 18% and make sure you have enough residence time in the steam chest in order to hydrolyze the starches. You must be wasting a lot of energy (in form of steam) by trying to transfer the heat into the corn by having an oversized steam chest.

2023-2-18·Five Tips for Making High Quality Flaked Corn. Use a surfactant or wetting agent like MYCOFLAKE ™. When applied to grain prior to introduction into the steam chamber, MYCOFLAKE permits moisture to uniformly and deeply penetrate each kernel. Surfactants work to reduce the surface tension of water, increasing moisture uptake by …

2023-2-18·Advanced industrial corn flakes making machine and assembly corn flakes production lines have formed the following modern corn flake production process. Mixing ingredients → twin-screw extrusion maturation → cutting and forming → pre-drying → pressing → high temperature baking → corn flakes. (1) Ingredients.

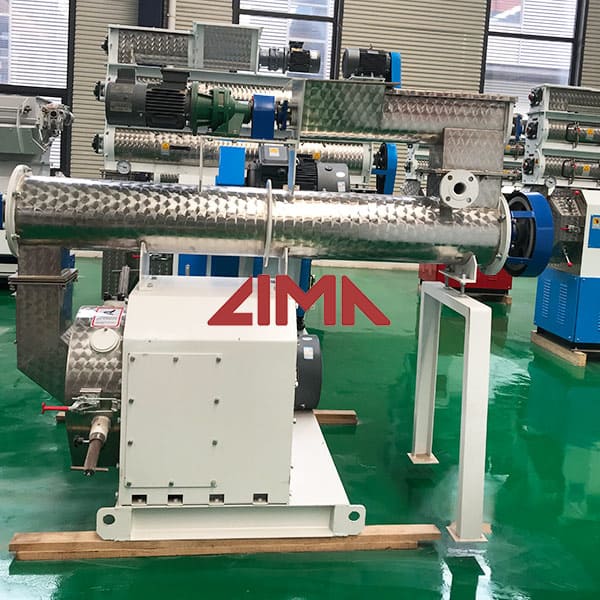

It’s what we call The CPM Advantage. Our high-capacity, high-efficiency flaking machines have the lowest operating cost in the industry; they keep running around the clock, year after year. That’s 24/7 performance with no unexpected downtime, and continuous quality flakes—even under the toughest flaking conditions. Find Your Rep.

The 30T corn maize flaking mill plant, we use the new technology design with Automatic control system, including precleaning ,cleaning , flaking, milling , auto-packing and PLC control system. It is steel structure workshop. precooked corn mill testing in Hongdefa factory. 2, Introduction about 30T/24H precooked corn mill machine.

2023-2-18·The MDFA is part of our integrated flaking line, designed to produce a highly efficient flaking process. This includes: steamer MBDA, flaking mill MDFA, roller temperature control unit and the downstream dryer OTW. The more successfully you can integrate components in your flaking line, the more efficient your process.

2002-6-1·Steam chests should be designed to allow a steaming time of at least 30 min at maximum roller mill capacity producing a flake of 0.31 kg/L (24 lb/bushel). As little as 5% moisture uptake during ...

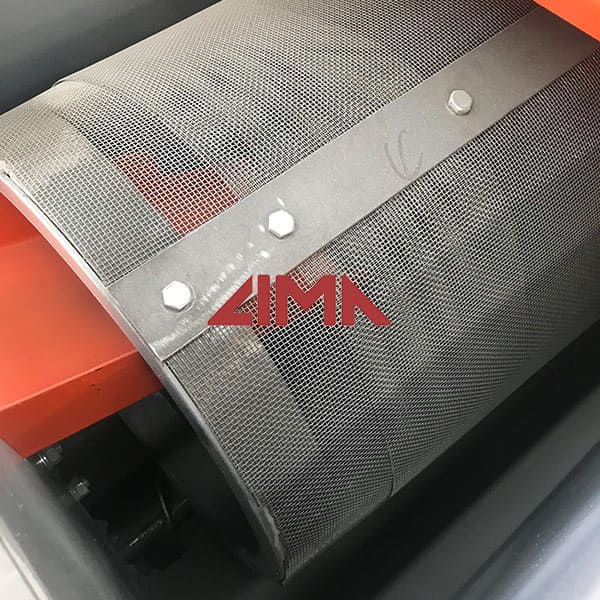

When it comes to flaking, size really does matter. Whether it’s corn or barley, milo or wheat, our equipment and applications expertise make our steam-flaking systems the best choice in the industry. Designed for efficiency and built for performance, our flakers are the most heavy-duty and highest-capacity machines in the industry. FLAKING MILLS

Dry milling and wet milling of cereal grains are used to produce ethanol and to partition the grains into an array of feed components (Figure 2).Wet milling is a more complex process and requires high-quality grains to produce high-value products suitable for human use. Some of the co-products, such as maize gluten meal, may be marketed in higher value …

2023-2-18·You will learn how to make a corn mill efficient - basic milling processes, machine design and plant operation. Everything from intake to the finished product. But you also get practical experience. You will spend time in front of key machines in our training center hall to learn cleaning, conditioning and milling techniques.

2019-3-5·January 23, 2019. Mohamad; The moisture content entering the flaking mill should be close to 18% and make sure you have enough residence time in the steam chest in order to hydrolyze the starches. You must be wasting a lot of energy (in form of steam) by trying to transfer the heat into the corn by having an oversized steam chest.

The corn flakes production line takes corn flour as the main raw material for production. Through raw materials mixing, twin screw extruder, high temperature extrusion, flaking, and pre-drying with a multi-layer mesh belt dryer, sugars spraying (such as maltose can be added through a sugar spraying and mixing system), and high temperature baking, …

Steam Flaking In animal feeding, steam flaked grains are used to improve feed efficiency and increase meat and milk production. Whole grains (corn, barley, wheat, rye) are conditioned with live steam to increase the temperature and moisture level, then flaked between large diameter rolls.

It’s what we call The CPM Advantage. Our high-capacity, high-efficiency flaking machines have the lowest operating cost in the industry; they keep running around the clock, year after year. That’s 24/7 performance with no unexpected downtime, and continuous quality flakes—even under the toughest flaking conditions. Find Your Rep.

The 30T corn maize flaking mill plant, we use the new technology design with Automatic control system, including precleaning ,cleaning , flaking, milling , auto-packing and PLC control system. It is steel structure workshop. precooked corn mill testing in Hongdefa factory. 2, Introduction about 30T/24H precooked corn mill machine.