Feed manufacturing – the pelletizing process ... Fine-grind hammer mills can grind product to 90 to 95 percent minus 420 μm (Bortone, 2005) or at best 300 µm (Chamberlain and Bortone, 2006). ... and for smaller shrimp, 150 to 180 µm (Chamberlain and Bortone, 2006). In shrimp feed mills, ingredients are ground after weighing and mixing ...

New design shrimp feed machine manufacturer shrimp feed mill plant FOB Price: USD $999 / Set Min. Order: 1 Sets; Hot selling shrimp feed equipment FOB Price: USD $2,000 / Set Min. Order: 1 Sets; Automatic shirmp feed hammer mill process flow of shrimp feed manufacturing FOB Price: USD $1,000 / Set Min. Order: 1 Sets

2021-7-28·Shrimp feed can be produced by two methods, pelleting or extrusion, depending on the dietary of the shrimp species. For the majority of the markets in Asia, pelleting solutions are still highly recommended. This page will give a comprehensive description of the pellet mill system. If you are interested to know more about the …

2005-6-1·In addition, one pelleted starter feed is more eco-friendly than the use of three crumbled starter feeds. In conclusion, this concept makes life for both, the shrimp farmer and the feed manufacturer, easier and more comfortable. This concept is an important link for sustainable shrimp farming. This revolutionary concept is an option, …

2022-7-21·Production and Formulation of Fish and Shrimp

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

SHRIMP/PRAWN PROCESSING PLANT (50 TONS/DAY)[CODE NO.4117] The frozen seafood market size has the potential to grow by USD 31.76 billion during 2020-2024, and the market’s growth momentum will accelerate during the forecast period because of the steady increase in year-over year growth.

2023-2-18·Best Shrimp Feed Portfolio for Faster Growth, Reduced Pond Pollution,Best FCR,Higher Profits. Pre Starter 101 For shrimps of 0.02 to 0.50 grams. Read more Starter 102 For shrimps of 1 to 1.75 grams. Read more Starter 102-P For shrimps of 5.01 to 6.88 grams. Read more Starter Plus 103

2019-9-9·aquaculture feed manufacturing today is the horizontal (Figure 18-4) mixers. Figure 18-4. Horizontal mixer. courtesy of Sprout Because of short mixing cycles that permit up to 20 batches per hour, most new shrimp feed mills are using horizontal drop-bottom mixers. Shrimp feed has bulk densities between 550-650 g/l and is a sinking feed.

2021-10-20·The demand for fishmeal from the shrimp industry is likely to keep rising, since it is projected that shrimp production will double by 2030 and this could lead to a 90 percent price rise in fishmeal and 70 percent increase in fish oil prices. Feed accounts for more than 50 percent of shrimp production cost and is considered to be one of the ...

2022-7-21·Production and Formulation of Fish and Shrimp

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

2021-2-10·The type of (RBV Round Bottom Vie) is more applied among various types of roller mill. Objectives of feed mill operations:-. Helpful to increase the productive value of feed. Increase the consumption rate of feed. After processing the feed become more palatable. The digestibility of feed becomes increases.

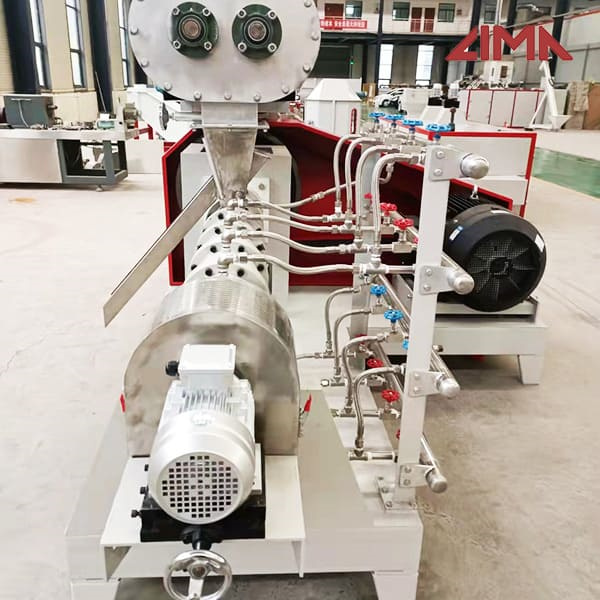

2022-4-14·An optimal layout of a shrimp feed production line will ensure the highest quality of product. A shrimp feed plant should follow a standard layout that enables it to meet the demands of its customers while maintaining a consistent production flow. After completing the design of the feed mill, the raw materials and ingredients are mixed and …

2019-12-18·Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm. This is a multi-functional feed pellet …