2012-6-28·• To moisturizing the feed particles, • To transfer the steam’s heat in to the particles. • Water, steam and oils are added respectively. • Conditioning gets some advantages in the system because; • Lengthens the life of extruder, • Increase the speed of production, • Increase the product quality.

2012-6-28·• It is hard to use different fish feed formulations (e.g. to increase the level of plant origin ingredients), • The level of crude fat is limited with 12-15%, • First investment of pellet mill seems cheaper or there is second hand chance to find and buy (It is about 200.000 Euros, if talk about complete fish feed

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage.

Ronald W. Hardy, Andreas Brezas, in Fish Nutrition (Fourth Edition), 2022 9.5.1.2 Fingerling feeds. Fish feed formulations for fingerling fish differ from fry feeds mainly in the dietary protein level, which is typically lowered by 12%–15% in feeds for fish once they reach 1–2 g.From this weight until fish reach 10–25 g depending on species, they are fed fingerling …

Lectures on Training Course in Fish Feed Technology. 1980. Fish Feed Technology. Food and Agriculture Organization of the United Nations (FAO)/ADCP/REP/80/11. Lewbart, G. A. 1998. Self-assessment Color Review of Ornamental Fish. Iowa State University Press. Ames, USA. Lewbart, G. A. 1991. Medical management of disorder of freshwater tropical …

Sinking And Floating Fish Feed Processing Line, 1000 Kg Per Hr. ₹ 35 Lakh. Proveg Engineering & Food Processing Private Limited. Contact Supplier. Fish Feed Making Machine, 110-140 kg per hr. ₹ 1.85 Lakh. Mechpro Engineering. Contact Supplier. Small Floating Fish Feed Making Machine, 100 kg per hr.

2012-6-28·• It is hard to use different fish feed formulations (e.g. to increase the level of plant origin ingredients), • The level of crude fat is limited with 12-15%, • First investment of pellet mill seems cheaper or there is second hand chance to find and buy (It is about 200.000 Euros, if talk about complete fish feed

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage.

Ronald W. Hardy, Andreas Brezas, in Fish Nutrition (Fourth Edition), 2022 9.5.1.2 Fingerling feeds. Fish feed formulations for fingerling fish differ from fry feeds mainly in the dietary protein level, which is typically lowered by 12%–15% in feeds for fish once they reach 1–2 g.From this weight until fish reach 10–25 g depending on species, they are fed fingerling …

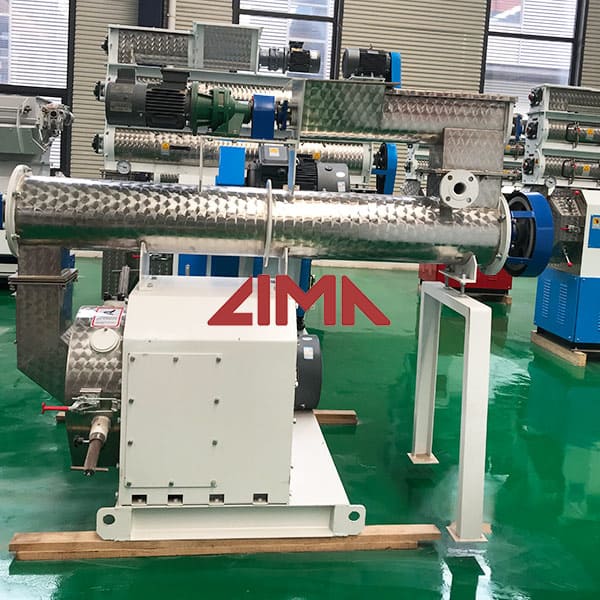

2016-10-2·produce floating fish feed pellets, slowing sinking pellets and sinking feed pellets. The main difference is whether need to connect a boiler/heater to send steam before extruding. Pellets can be produced from both pelletizer and extruder. Pelleting was introduced into Europe about 1920 and into the United States feed industry

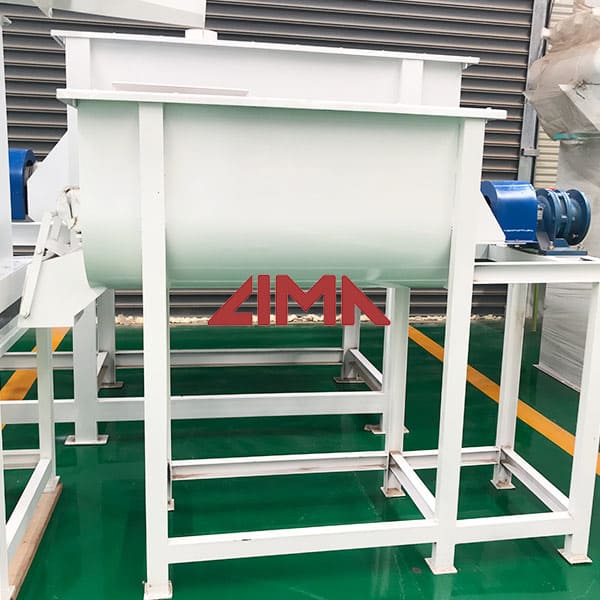

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

2023-2-13·1200-1500KG/H Fish Extruded Feed Production Plant In Puerto Rico. A fish feed extruder purchased by customers from Puerto Rico this time will be used in the 1200-1500kg/h aquatic floating fish feed mill plant. Puerto Rico is located in the eastern part of the Greater Antilles in the Caribbean Sea. Most of the Caribbean countries are …

2014-3-3·A diagram of a typical pelleting system is shown in Figure 1. Mash Supply Bins. The system begins with the supply of the feed (mash) to be pelleted. The mash is usually a mixture of relatively dry ingredients that has been formulated and blended prior to delivery to the supply bins. This mash is a mixture of particles of different sizes ...