2017-10-18·Sugarcane bagasse pellets: characterization and comparative analysis Acta Scientiarum. Technology, vol. 39, núm. 4, octubre-diciembre, 2017, pp. 461-468 ... capacity for removing 3,000 kg of water per hour. ... machine is driven by a 300 HP electric motor at 1,190 rpm, pelletizing a matrix of 740 mm outer

300-500kgs/hour Flat Die Pellet Machine TCZL400. This machine is our flat die pellet machine, power from 15kw to 55kw ,the capacity from 100kgs/hour to 1000kgs/hour. This machine can be used for making biomass pellets and animal feed pellets, suitable for small scale pellet production. More Information. Get A Quote Now.

2022-5-27·China High Capacity 30kw Flat Die Wood Pellet Mill Making Machine, Find details about China Feed Machine, Feed Pellet Machine from High Capacity 30kw Flat Die Wood Pellet Mill Making Machine - Henan Lerford Machinery Equipment Co., Ltd.

2020-4-4·11.71 MJ/kg. These properties were compared to other pellets and standard and it was suggested that the filter cake pellets can be used together with bagasse as fuel for a boiler in a sugarcane industry. 1. Introduction Currently, there are 55 sugar mills with a total capacity of 100 million tons per year in Thailand [1].

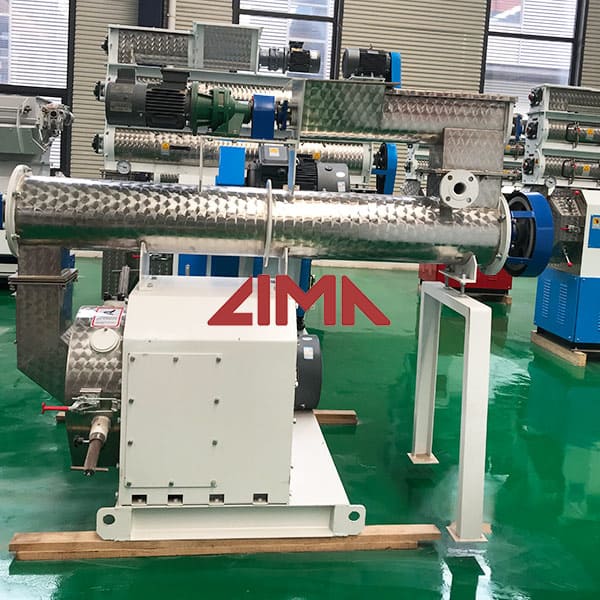

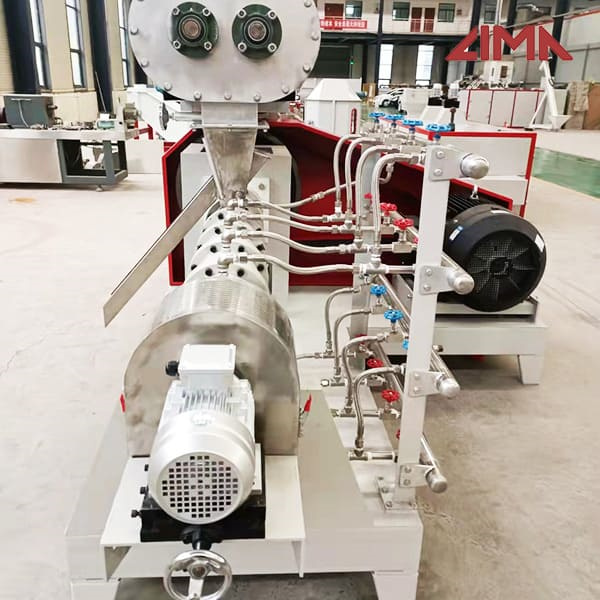

2022-3-30·Flat die pellet machine; Feed pellet mill; Small pellet mill; Wood crusher. Wood chipper; Wood Pallet Crusher; ... Bagasse powder materials are feed into the sugarcane bagasse pellet machine, ... XGJ560 POWER:90KW 132KW 160KW CAPACITY:1-2.5T/H XGJ850 POWER:250KW CAPACITY:3.5-4.5T/H.

2022-8-29·Flat Die Manufacturers, Factory, Suppliers From China, Standing still today and searching into the long run, we sincerely welcome shoppers all around the globe to cooperate with us. ... 11Kw(300-500Kg/h) 15Kw(500-700Kg/h) 22Kw(700-900Kg/h) Crushing Machinery. Straw Crushing; Wood Chipper; ... Product Name:Biomass Pellet Machine …

Product Description. SKJ2-300 30kw 600-1000kg/H Flat Die Type Farm Using Grass Feed Pellet Press . Introduction of grass feed pellet press. The SKJ garss feed pellet press is the ideal equipment for farm using, it is good for making different kind of materials into animal feed pellets, for feeding different type of livestock, such as cow, cattle, horse, sheep, …

2022-12-7·Before the storage stage, bagasse pellets need to be created from the fibrous raw source. The first step in the bagasse pellet making process is drying. The bagasse needs to be heated to high temperatures to remove the moisture. The goal is to decrease the moisture content from 40 to 50 percent to 12 percent or less.

Quality China supplier sugarcane bagasse/beet pulp pellet line/ complete wood pellet line - find quality Biomass Pellet Line, Wood Pellet Mill & Biomass Pellet Line from Shandong Tony Environmental Protection Sci-Tech Co., Ltd. of China Suppliers - 141276690.

2022-2-22·The production of sugarcane bagasse per year in Brazil is 75~90 million tons. About 90% or more is used as fuel to supply power for factory. With wood pellets making machine, bagasse can be extruded into pellets fuel. Some sugar mill owners sell their excess sugarcane bagasse pellets to other factories with boilers or export them to …

Ring die pellet machine; Flat die pellet mill 2 rolls; Flat die pellet mill 3 rolls; Feed pellet mill; Wood chipper. ... Three tones of bagasse will be produced when squeezing 10 tons of sugarcane. In the past sugarcane bagasse is worthless residue, but now it is an important biomass material which can be used for the production of ethanol and ...

2022-8-29·Model Power(kw) Capacity(t/h) Weight(t) SZLH350 30 0.3-0.5 1.2 SZLH450 45 0.5-0.7 1.4. Biomass mainly includes wood and agricultural byproducts. Transforming them into biofuel not only protects environment but also take full …

2022-5-27·China High Capacity 30kw Flat Die Wood Pellet Mill Making Machine, Find details about China Feed Machine, Feed Pellet Machine from High Capacity 30kw Flat Die Wood Pellet Mill Making Machine - Henan Lerford Machinery Equipment Co., Ltd.

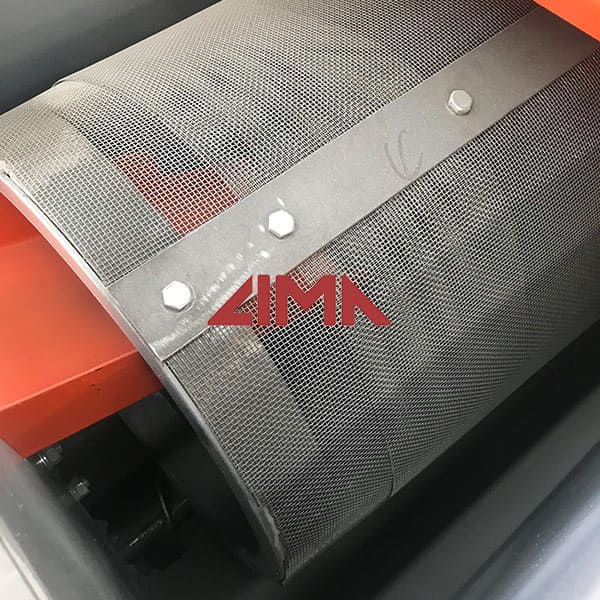

How to Make Bagasse Pellets. Firstly, bagasse waste will be dried down to 10-12% moisture. Secondly, dried bagasse needs to be crushed into powder by a hammer mill usually with ø 5 mm hammer mill screen. Thirdly, it will be conveyed into bagasse pellet mill in small scale pellet production. For large scale production, ring die pellet mill can ...

2022-8-29·SZLH660 pellet machine is our latest design for vertical ring die pellet machine.With 132kw motor,the machine's capacity is 1.5-2.0t/h and sometimes it could reach 2.5t/h.Because of its good performance,it is very popular on the market.The reducer's life is extended 3 times than other model.The roller bearing adopts independent …

2018-11-5·Biocomposites are materials formed by mixing a polymer matrix and a filler or reinforcement, with the characteristic that at least one should be of biological origin. For this study, biocomposites were obtained from natural fibers of cane bagasse and polypropylene, using bagasse from postindustrial sources, originating from the …

2022-12-7·Before the storage stage, bagasse pellets need to be created from the fibrous raw source. The first step in the bagasse pellet making process is drying. The bagasse needs to be heated to high temperatures to remove the moisture. The goal is to decrease the moisture content from 40 to 50 percent to 12 percent or less.