1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is …

production making machine. hot sale parts. mill power. fish cutting machine. farming equipment system. More. We find 600 products about floating fish feed extruder machine from 176 manufacturers & suppliers. Hot sale in Nigeria best price floating fish feed pellet extruder making machine Supplier's Choice.

Sjsz110/220 Conical Twin- Screw Lvt/PVC/WPC/Spc Flooring Production Line/Making Machine/Extrusion Line/ Extruder. US$ 105000-350000 / Line. (FOB Price)

Screw extruders are divided into single screw and multiscrew extruders. Single screw extruders are most popular for their low cost, simple designs, ruggedness, and reliability. Typical sizes vary from 1 to 6 inch (25 to 150 mm) and L / D ratio from 20 to 30 with 24 being most common. Basic operation of a single screw extruder is described in ...

2021-12-28·Using a gradually reducing channel depth in the “compression section” of the screw forces any unmelted polymer closer to the barrel wall, where it gets the maximum shear. 1. Screw channel is filled with unmelted polymer leaving the feed throat. 2. Due to barrel heating, a thin film of melt forms on the barrel wall. 3.

Food extrusion equipment market , the single screw extruder is more affordable and economical to operate . twin screw extruders are more productive; more advanced and have more extensive application than single screw extruder machines. the twin screw extruder have wider benefits which include higher levels of flexibility in production, higher ...

2016-12-8·Extrude Fish Feed is one of the most difficult application for an extruder/expander due to the nature of the ingredients and also due to the configuration of the worms on the main shaft and the restriction applied on the extruder's discharge at the die plate. Most of my experience extruding Feed or Cereals have been made using single …

2010-8-13·Single-Screw Extrusion THE EXTRUDER CHARACTERISTIC In general the die restricts the flow somewhat, but not completely. Combining equations 4.6, 4.7, and 4.8, we get the EXTRUDER CHARACTERISTIC: Q = αN − β µ ∆P (4.13) Figure 4: The Extruder Characteristic for a Newtonian Fluid is a linear relation between Q and ∆P.

2023-2-15·The multifunctional single-screw extruder offers a modular design to meet a wide range of process requirements for your pet food and aqua feed production. Capacity, screw speed, torque and pressure options provide excellent versatility. Watch the video.

ANDRITZ offers unique, high-capacity extrusion lines for the production of all kinds of feed for fish and shell fish. The ANDRITZ extruders ensure that the feed has the right physical properties – giving it the correct sinking attributes according to where in the water the feed should be accessed. ANDRITZ single screw extruders represent ...

3 The advanced single-screw and twin-screw extrusion concept FEATURES Type EX0618 EX0621 EX1021 EX1250 EXTS718 Transmission belt belt belt gear gear third party Bolt barrels - - - x x Screws pinned pinned pinned pinned spline Water cooling or heating jackets x x x x x Liquid injection points x x x x x Screw pushout - - - - x Dual and single …

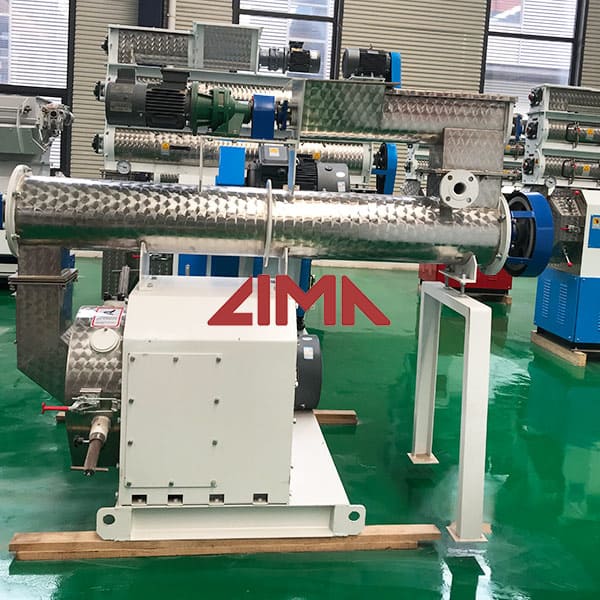

2016-10-2·aquaculture. Fish feed extruder comprises of hopper, a barrel which houses, the screw conveyor, the cutting knife, the die, a heater etc. It can be divided into wet and dry type mill. They both can produce floating fish feed pellets, slowing sinking pellets and sinking feed pellets. The main difference is whether need to connect a

Screw extruders are divided into single screw and multiscrew extruders. Single screw extruders are most popular for their low cost, simple designs, ruggedness, and reliability. Typical sizes vary from 1 to 6 inch (25 to 150 mm) and L / D ratio from 20 to 30 with 24 being most common. Basic operation of a single screw extruder is described in ...

For Sale - Used Plastic Extruders, Twin Screw Extruder, Conical Screw Pipe Extruders ... 28:1 L/D, Air cooled barrel Jacketed feed section Driven byt 7.5 kw ..... UM 22260:-USA . Contact Supplier ... TCP-065 Single Screw Extrusion Plant Equipments to produce RPVC Pipe and Profile die tools for making 12 mm, 19 mm, 25 mm & 32 mm Size Casing ...

2022-11-7·It is therefore important to consider the guidelines above when selecting the type of technology to invest in. In conclusion, the single screw extruders are more affordable and economical to operate unlike the twin-screw extruders. On the other hand, twin screw extruders are more productive; more advanced and have more extensive …

2010-8-13·Single-Screw Extrusion THE EXTRUDER CHARACTERISTIC In general the die restricts the flow somewhat, but not completely. Combining equations 4.6, 4.7, and 4.8, we get the EXTRUDER CHARACTERISTIC: Q = αN − β µ ∆P (4.13) Figure 4: The Extruder Characteristic for a Newtonian Fluid is a linear relation between Q and ∆P.