China Extruder Feeder manufacturers - Select 2023 high quality Extruder Feeder products in best price from certified Chinese Extruder Machine, Screw Extruder suppliers, wholesalers and factory on Made-in-China.com ... Most Popular Automatic Screw Force Feeder for Plastic Extruder Machine . US$ 2300-3200 / Piece (FOB Price)

Besides automating operations at your workplace, a extruder screw feeder offers much more perks, including adaptability, higher levels of operations control, and risk reduction. Conveyor machinery is highly adaptable to various processing functions and boasts the flexibility to adjust to various material sizes and weights.

2014-2-4·Aquafeed Twin Screw Extrusion Processing J.M. Bouvier and A. Brisset Clextral Group Z.I. de Chazeau, B.P. 10 42 702 Firminy – France Abstract Aquatic feeds require specific physical and nutritive properties and have to comply with the fish behaviour. Fish meal and fish oil are frequently used as raw materials together with cereals …

Extruder feeders with different technologies. Since 1990, Movacolor has been developing and marketing high quality extruder feeders based on gravimetric dosing technology, optometric dosing technology and volumetric dosing technology, all of which are Industry 4.0 ready. At the start of the company, Movacolor began with the development and …

vibrating feeder F series. electromagnetic automatic PLC-controlled. The Electromagnetic Feeder, manufactured by Tarnos, is specifically designed for feeding a broad variety of bulk material, from storage hoppers or silos to belt conveyors, mills, dryers, mixers applications.

23. Austria Sells Industrial Dog Food Machine 100kg/h. 24. 50Kg/H Small Dog Food Extrusion Machine For Sale In Botswana. 25. Sudan 50kg/h Small Dog Food Production Line. 26. Algerian Dog Food 300kg/h Production Line. single screw cooking forming extruder manufacturer of semi-finished pellets chips and snacks making.

2021-10-16·The success of an extrusion process is indeed as much due to the design of the raw material dosing system as it is due to the subsequent screw profile of the extruder. Feeding the materials in an uncontrolled way will indeed lead to formulation problem in the extruder and a process difficult to control or even generating out of spec …

2016-12-8·To do sinking pellets you need: 1. To have a technological opening in the penultimate section of the extruder. 2. Modification of the screws must be assembled for sinking feeds. 3. The area of the holes in the matrix must meet the requirements of sinking feed. 4. Composition of the recipe table.

China Extruder Feeder manufacturers - Select 2023 high quality Extruder Feeder products in best price from certified Chinese Extruder Machine, Screw Extruder suppliers, wholesalers and factory on Made-in-China.com ... Most Popular Automatic Screw Force Feeder for Plastic Extruder Machine . US$ 2300-3200 / Piece (FOB Price)

2019-9-5·However, extrusion is a process that involves many parameters that need to be optimized for desirable end properties. These findings guide fish feed manufacturers on the optimum conditions for single screw extruders for production of feeds with desirable properties especially for the fish types that are top feeders. In addition, the

Compound Extruder Machine Quality Polymer Compounding Machine Twin Screw Extruder With Side Feeder. $10,000.00-$120,000.00/ set. 1 set (Min Order) Nanjing Yongjie Qixin Machinery Equipment Co., Ltd.> CN 7 YRS. 94.3% Response Rate. 5.0 (4) |. "Good job". Air-cooling hot-face pelletizing line >. PVC pelletizing machine >.

Extruder feeders with different technologies. Since 1990, Movacolor has been developing and marketing high quality extruder feeders based on gravimetric dosing technology, optometric dosing technology and volumetric dosing technology, all of which are Industry 4.0 ready. At the start of the company, Movacolor began with the development and …

2012-6-27·AET's screw feeders provide a steady flow of material into the extruder insuring a constant output. They are most often used in scrap reclamation and compounding applications. They effectively feed the most difficult materials such as powders, foam scrap, chopped film, fiber scrap, and other low bulk density material.

2021-10-16·The success of an extrusion process is indeed as much due to the design of the raw material dosing system as it is due to the subsequent screw profile of the extruder. Feeding the materials in an uncontrolled way will indeed lead to formulation problem in the extruder and a process difficult to control or even generating out of spec …

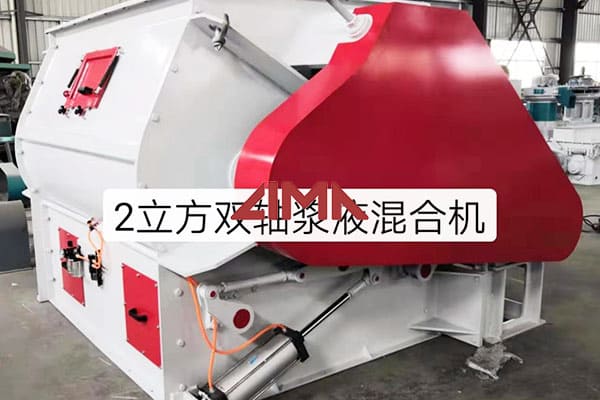

SINGLE SCREW EXTRUDER VS TWIN SCREW EXTRUDER. 1. Capacity: Single screw is suitable for starch extrusion cooking but without puffing. The material stays in the food extruder machine for a long time; the twin-screw has good mixing and cooking ability, the material is short in the extruder, and is suitable for powder processing. 2.