Fish feed crusher is used for grinding raw materials into small pieces with proper …

2023-2-16·Floating aqua feed for tilapia, catfish, eels, etc. We create complete solutions for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extruding process to meet your demands and optimize …

2012-6-28·• It is hard to use different fish feed formulations (e.g. to increase the level of plant origin ingredients), • The level of crude fat is limited with 12-15%, • First investment of pellet mill seems cheaper or there is second hand chance to find and buy (It is about 200.000 Euros, if talk about complete fish feed

fish (Atoyebi, 2007). There are two types of pellet making machines that are known univer-sally. These are the disc-die type, and ring die type, (Kaankuka and Osu, 2013). The Chinese, Asians and Europeans made many modern disc die and ring die pellet machines (ASTW, 2014 and LIVI, 2014).These modern fish meal plants

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage.

2014-2-1·Design and fabrication of fish feed pelleting Machine and Dryer Thesis submitted to the Department of Mechanical Engineering F,U,T Minna pp 1-79. [2] Hasting, W.H and D. Higgs (1980): feed milling ...

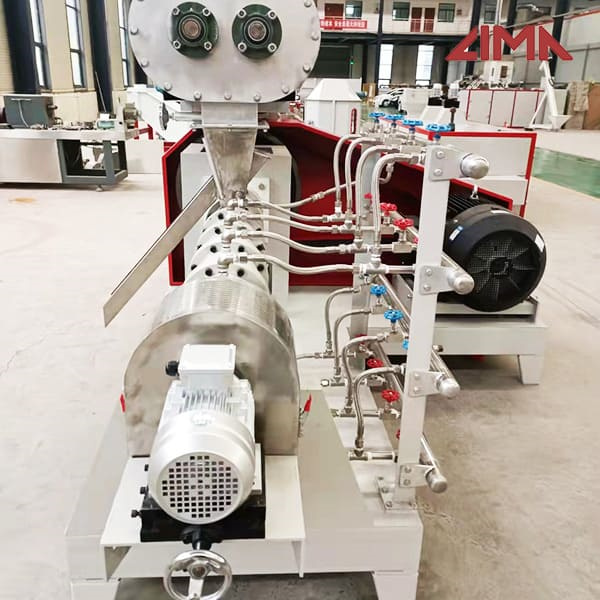

To mix different flour materials together and evenly. 3. Extruding and pelleting. Fish Feed Extruder. To make fish feed pellet, the material is processed by high temperature and pressure and pelletized into round pellets, suitable for feeding fish, we could produce both floating fish feed and sinking fish feed. 4.

2022-3-8·Hence, the local fish farmer, in Ratnagiri in particular, cannot afford to utilize the sophisticated fish food pelleting machine. This work aims at designing and developing a fish food pelleting machine and evaluating its performance. 3. METHODOLOGY Tool Used 1. CATIA V5 (Design of components and structure) 2.

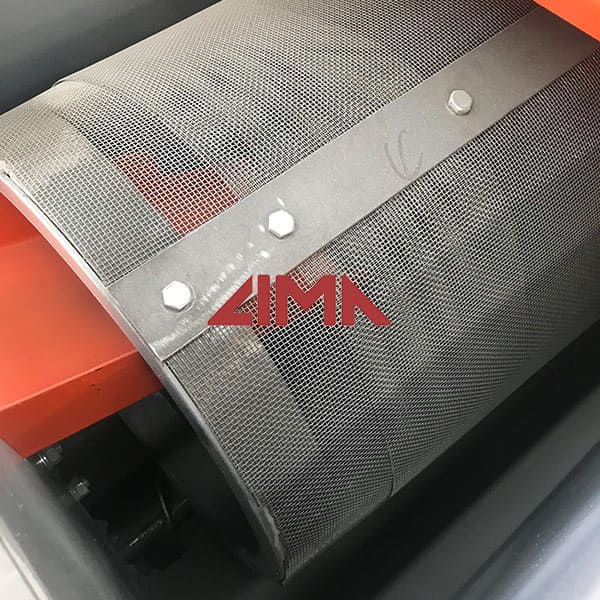

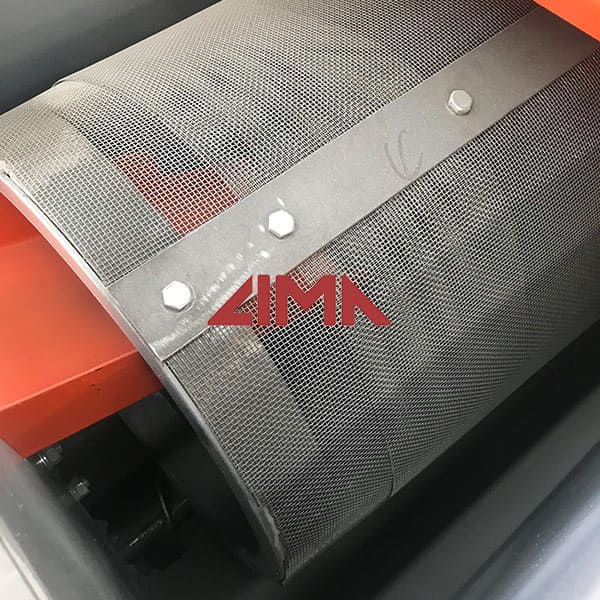

Pelleting is a main step of any Floating Fish Feed Plant. It is a process of converting any powder to solid shape called pallet. In this process the powder material is extruded through a well-designed die with the help of rollers to convert it in to pellets. The quality & production of pellet mill depends on so many parameters. - Feed formula

2021-3-16·15TPH poultry feed plant project; 40TPH fish feed mill plant; 10TPH chicken feed plant; ... how to find a cost effective fish feed pelleting machine; ... Company Anyang Best Complete Machinery Engineering Co., Ltd - Tel: 0086-372-5965148 - Fax: 0086-372-5951936

2023-2-16·Floating aqua feed for tilapia, catfish, eels, etc. We create complete solutions for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extruding process to meet your demands and optimize …

2012-6-28·• It is hard to use different fish feed formulations (e.g. to increase the level of plant origin ingredients), • The level of crude fat is limited with 12-15%, • First investment of pellet mill seems cheaper or there is second hand chance to find and buy (It is about 200.000 Euros, if talk about complete fish feed

fish (Atoyebi, 2007). There are two types of pellet making machines that are known univer-sally. These are the disc-die type, and ring die type, (Kaankuka and Osu, 2013). The Chinese, Asians and Europeans made many modern disc die and ring die pellet machines (ASTW, 2014 and LIVI, 2014).These modern fish meal plants

Our KAHL fish feed plants are equipped with the latest process technology, the core of which is the extrusion system with the extruder OEE 25 NG and the process control system ESEP. Process sequence. A fish feed plants includes several individual machines for conveying, proportioning, pre-treatment and subsequent cooling and storage.

2014-2-1·Design and fabrication of fish feed pelleting Machine and Dryer Thesis submitted to the Department of Mechanical Engineering F,U,T Minna pp 1-79. [2] Hasting, W.H and D. Higgs (1980): feed milling ...

2023-1-19·This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone ...

To mix different flour materials together and evenly. 3. Extruding and pelleting. Fish Feed Extruder. To make fish feed pellet, the material is processed by high temperature and pressure and pelletized into round pellets, suitable for feeding fish, we could produce both floating fish feed and sinking fish feed. 4.

Everything you need to know about feed pelleting in a convenient, downloadable guide, from sources you trust. The FREE Feed Pelleting Reference Guide is from WATT Global Media and K-State University, as individual, topical PDF files within each of the six sections of the guide. Borregaard LignoTech.

2021-3-16·15TPH poultry feed plant project; 40TPH fish feed mill plant; 10TPH chicken feed plant; ... how to find a cost effective fish feed pelleting machine; ... Company Anyang Best Complete Machinery Engineering Co., Ltd - Tel: 0086-372-5965148 - Fax: 0086-372-5951936